8 Servicing work

NGW 300 / LGW 300 / GBW 300

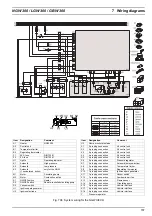

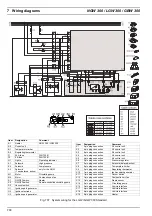

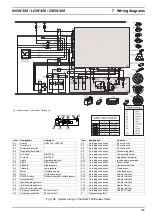

802

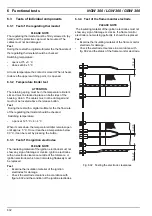

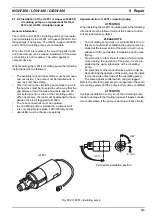

8.5.1 Disassembling and mounting the burner head

CAUTION

The ignition spark generator is operated at high voltage.

Before disassembly, the wiring harness plugs in the

vehicle must be disconnected. Otherwise, there is a

danger of death. If the burner head is mounted again,

reconnect the plugin the vehicle

ATTENTION

•

Basically, it is necessary to disconnect not only the

electrical connection to the temperature limiter and

the regulating thermostat, but also the electrical

connection from the vehicle to the control unit, and to

loosen the reference pressure line connectors and the

gas supply hose on the burner side. Otherwise,there

is a risk of damage to the burner and/or the electrodes

during the repair.

•

Pull out the burner head carefully from the heat

exchanger and slide it in order to prevent its being

damaged.

PLEASE NOTE

When the burner head is dismounted, the following

components become accessible:

–

Ignition electrodes

–

Flame monitor electrode

–

Fuel pipe

–

Combustion chamber

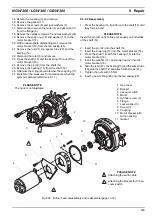

8.5.1.1 Disassembly

1. Disconnect the electrical line from the control unit to

the vehicle.

2. Disconnect the electrical lines to the temperature

limiter and the regulating thermostat (1, fig. 801).

3. Loosen the gas supply hose (6) and the reference

pressure line (7), if they are connected.

4. Loosen both nuts (4) so far that it is possible to

remove the screws (3) by swiveling.

5. Remove the screws (3) by swiveling.

6. Carefully dismount the burner head (5).

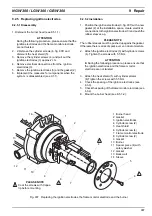

8.5.1.2 Mounting

ATTENTION

During the following procedure, please ensure that the

ignition electrodes and the flame monitor electrode

are not twisted.

1. Slide the burner head (5, fig. 801) carefully (5, fig. 801)

into the reassembly position.

2. Swivel in the screws (3).

3. Tighten both nuts (4) with 7.5 Nm.

4. Attach the gas supply hose (6) and, if applicable, the

reference pressure line (7).

5. Re-establish electrical connections (1) to the

temperature limiter and the regulating thermostat.

PLEASE NOTE

Ensure that the temperature limiter’s and the regulating

thermostat’s electrical connections are wired, using the

proper colours.

6. Re-establish the electrical connection to the vehicle’s

wiring harness.

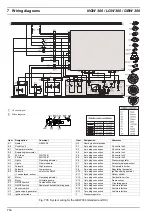

Fig. 801 Dismantling and mounting the burner head

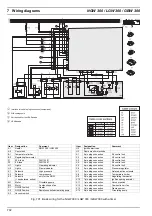

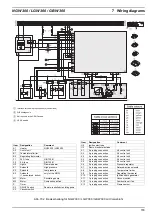

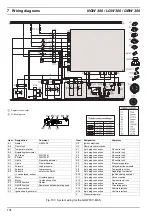

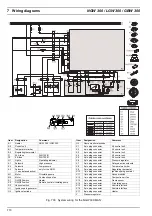

8.6

Visual inspections and.

installation regulations

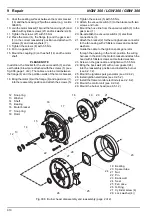

8.6.1 Connection to the vehicle’s cooling system

The heater must be installed in as low a position as

possible, so that the heater and the circulating pump are

sure to be bled automatically. This is particularly

applicable, as the circulating ump is not self-priming.

As shown in fig. 802, the heater must be connected to the

vehicle’s cooling system. The amount of coolant present

in the circuit must amount to 10 l at least.

In the vehicle’s cooling system, only only high pressure

valves with an opening pressure of at least 0.4 bar and

max. 2.0 bar are used.

Basically, the coolant hoses provided by Spheros must be

used. If this is not the case, the hoses must conform to the

DIN 73411 standard, at least. Hoses are to be installed

free of kinks (for flawless bleeding) and going upwards, if

possible. Hose connections must be secured with hose

clamps to prevent them from slipping.

1 Electrical connections

2 Split pin (2)

3 Screw

4 Nut (2)

5 Burner head

6 Gas connection

7 Reference pressure

1

2

3

4

5

6

7