9 Repair

NGW 300 / LGW 300 / GBW 300

904

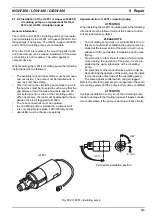

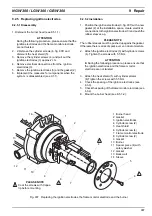

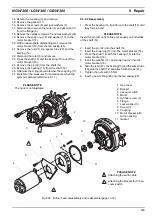

Implementation: Aquavent 6000 S circulating pump

ATTENTION

When installing the Aquavent 6000 S circulating pump,

the following directions must be followed without fail.

Failure to so will exclude warranty claims.

HINWEIS

•

In contrast to the U 4851 circulating pump, the Aqua-

vent 6000 S must be integrated into the vertical instal-

lation position in such a way that the pump head is

above the motor.

•

The circulating pump is not self-priming. Due to this

lack of automatic ventilation,the pump must be instal-

led at the lowest point of the water circuit in com-

pliance with the permissible installation position

(see fig. 903).

•

The hoses must be laid without kinks and going up-

wards. Hose connections must be secured with hose

clamps to prevent them from slipping.

•

No solenoids or other shut-off valves which could be

closed during the operation of the pump, must be instal-

led on the water infeed side of the circulating pump.

The same applies to filters which can get clogged.

•

Before the circulating pump is put into operation the

vehicle’s cooling system and the pump body must be

ventilated.

•

InThere are no consumable parts installed in the cir-

culating pump. It is also possible to replace the motor

without dismantling the pump head.

ATTENTION

A dry run of the circulating pump of up to 45 mins. Is per-

missible. Flawless ventilation is detectable, if the pump is

working virtually silently.

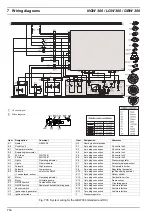

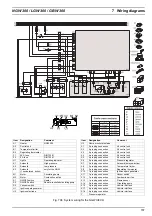

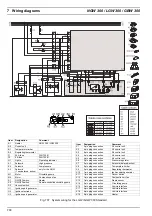

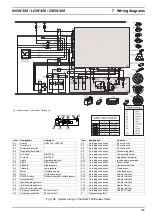

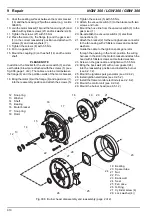

0-90°

5°

0-85°

Permissible installation position

Aquavent 6000 S

Fig. 903 Aquavent 6000 S circulating pump