4.

INSTALLATION – ELETTRICAL CONNECTION

4

a- The connection to the electrical power supply

system must be done according to the standard

in force.

b-

Before connecting the appliance, make

yourself sure that the voltage and the frequency

correspond to those stated on the data plate of

the appliance.

c- The appliance must be placed so that the

connection plug to the network can be easily

reached.

d- Place an omni-polar switch between the

appliance and the network. The omni-polar

switch must have the following characteristics:

-

must be easily reached after the installation;

-

the contacts of the switch must have a minimum

opening distance of 3 mm;

-

must have an appropriate input (for example,

magneto-thermal switch.

When the appliance is working the power supply

voltage must not diverge from the value of the

nominal voltage, written on the technical data

plate, by more than ± 10%.

b- The appliance must be connected to the ground

line of the network.

Moreover, the appliance must be included in

equipotential system whose efficiency must be

properly checked according to the

current law. This connection must

be done between the different

appliances using the terminal

marked with the symbol:

The equipotential conductor must have

a minimum section of 10 mm

2

.

ENGLISH

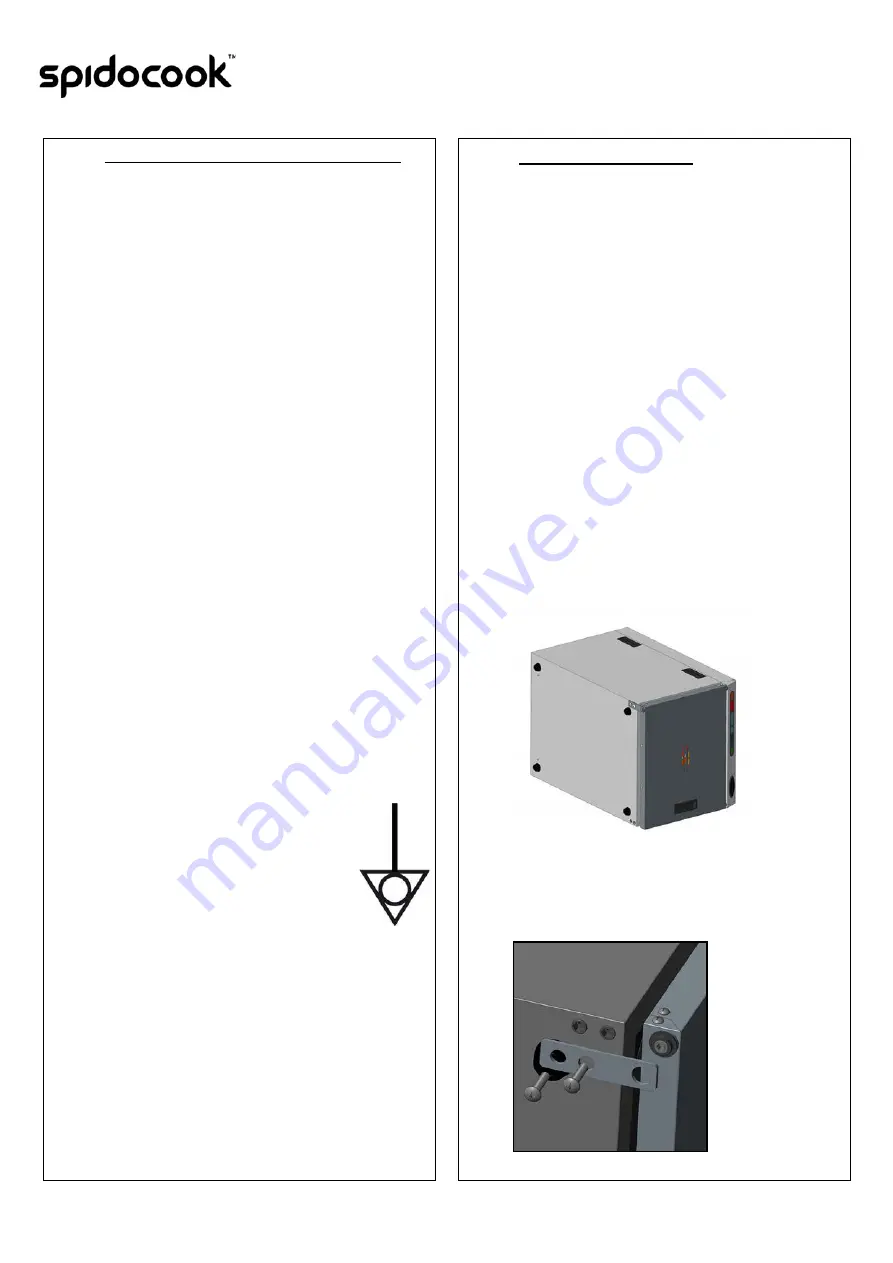

5.

REVERSAL OF THE DOOR

To meet the customers’ need, the appliance

is equipped with a reversible door. With this

characteristics, the user can choose, at any time, on

which direction he/she wants to open the door.

Needed equipment:

• Medium size screwdriver with Philips driver;

• Small size screwdriver with Slotted driver

Procedure:

1.

Disconnect the appliance from the electrical power

supply and wait for the appliance to cool down.

2. Remove eventual trays containing food from the

cavity.

3. Lay the oven on the side so that the fulcrum of

the door is on the top (see following picture).

4. With the screwdriver with Philips driver, unscrew

anticlockwise both the screws that fix the stirrup

(see following picture).

ENGLISH