10

Section 5

Recirculation Systems

A problem many hot water systems encounter is the

delayed supply of hot water to fixtures that are a substantial

distance from the heater. During idle periods, heat loss in

the piping system will result in cool water at the tap until hot

water produced from the heater is able to reach that point.

Delays in providing hot water at the tap can result in user

dissatisfaction.

The compactness of the RediHeat permits installation close

to the point of use in many cases. However, in systems with

long pipe runs, conditions may exist where the supply of hot

water at the faucet will be delayed.

To provide instantaneous hot water on demand in systems

with long pipe runs, various methods can be utilized. The

appropriate system will be influenced by site conditions,

plan requirements, and user preference.

The following describes several systems and their interaction

with the RediHeat instantaneous heater:

A. Heat Tape Systems

Many building systems avoid the costly pipe runs of

conventional loop or return systems. Instead, electrical

resistance heat is applied to the pipe in tape form to replace

heat lost from the system. This method can be very effective

and the RediHeat will function perfectly with this type of

system. Heat tape installed up to the hot water outlet of the

control valve will assure maximum performance.

B. Bleed System

This system consists of a single line distribution pipe with a

thermostatically operated bleed valve. A temperature switch

is set to open the bleed valve if the line temperature falls

below the system set point. Upon opening, water in the line

is dumped to drain until heated water from the RediHeat

fills the line and signals the valve to close. This cycle will

continue to hold the water temperature within set limits.

This system eliminates the costs of return piping and

circulation pumps, however the cost of water consumption

may prove too high for many installations.

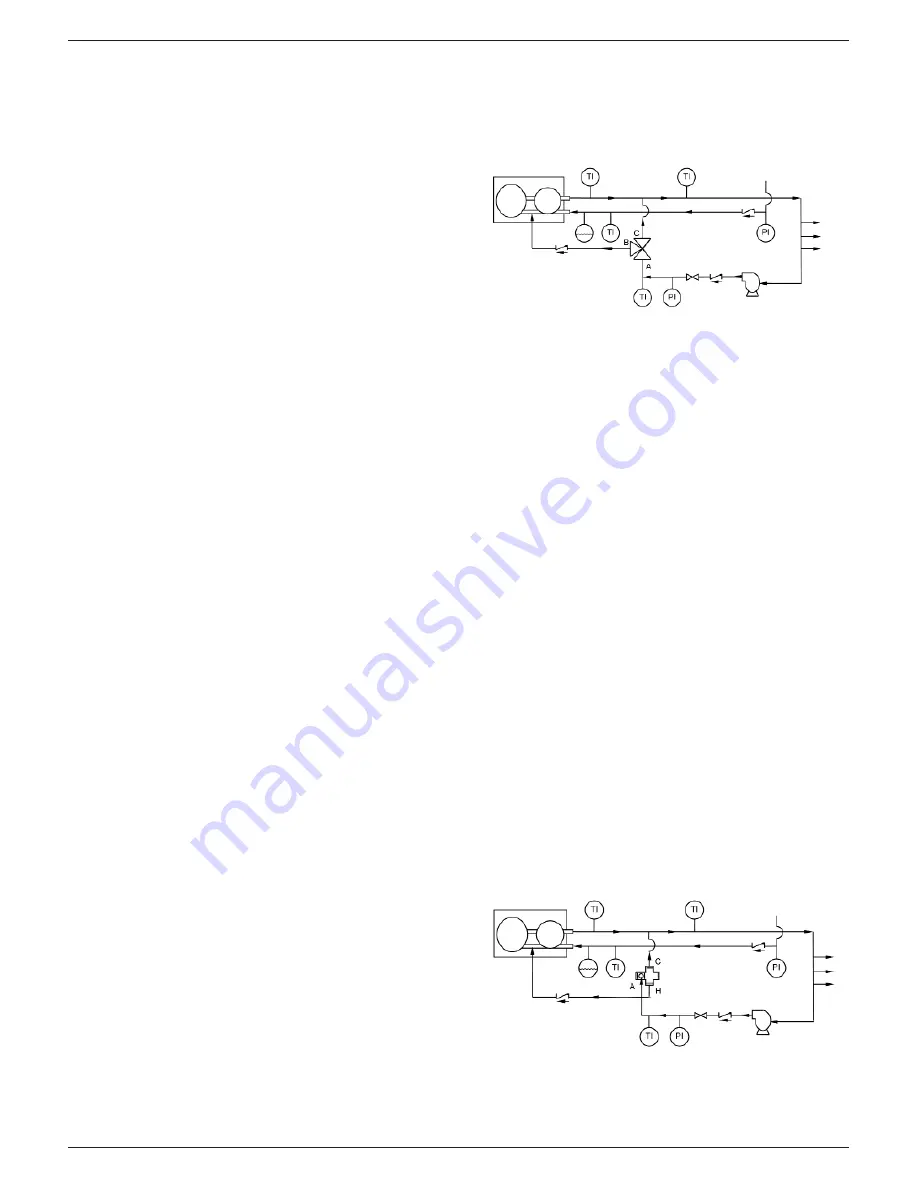

C. Forced Recirculation Loop - Diverting Valve with

Fixed Thermostat:

Most systems incorporate a circulating pump to maintain

constant flow in a forced recirculation loop. The RediHeat

is used to maintain loop temperatures as well as supply

demand requirements. The system includes a self contained

3-way thermostatic type diverting valve to direct the

recirculated water flow as required. The diverting valves

normally are provided with fixed thermostatic elements.

Models with adjustable elements are also available (see

section D).

Water flow in the system is governed by the temperature

of the recirculating loop. When the loop is at the desired

temperature, the flow of recirculated water by-passes the

RediHeat. As the temperature in the loop decreases due

to heat loss through the piping, the thermostatic element

responds and causes a portion of the water to be diverted

through the RediHeat. Typical recirculated flow rate is

10% of the RediHeat capacity, however more accurate

calculation methods should be used in complex systems.

Installation of the diverting valve is as shown. If you have

any questions regarding installation, contact Spirax Sarco.

Incorrect installation can lead to serious overheating of the

water, resulting in dangerous temperatures.

D. Forced Recirculation Loop (Diverting valve with

adjustable thermostat):

In addition to the fixed thermostatic element diverting valve,

Spirax Sarco offers as an option an adjustable diverting

valve. The adjustable diverting valve can be used to provide

additional flexibility in the temperature of the hot water when

the system is in the recirculation mode. The valve supplied is

a Lawler Thermostatic Water Controller or equal. As Spirax

Sarco uses the valve in a non-typical manner, do not follow

the standard installation instructions supplied by the valve

manufacturer. The following should be used as a guide for

installation of this system.

Connect the Lawler port labeled “outlet” to the recirculating

loop return line. This is the flow into the valve from the

circulating pump, indicated as “A” below.

Connect the port labeled “H” (hot water inlet) to the cold

water supply line feeding the RediHeat. This port will open

when the recirculation loop water has cooled, and sends a

portion back to the RediHeat for reheating.

Connect the port labeled “C” (cold water inlet) to the hot

water supply line feeding the recirculation loop. This port

is open when the recirculation loop water is at the desired

set point and allows the recirculating water to by-pass the

RediHeat.

Installation of the diverting valve is as shown. If you have

any questions regarding installation, contact Spirax Sarco.

Incorrect installation can lead to serious overheating of the

water, resulting in dangerous temperatures.

Diverting Valve

(Fixed Thermostat)

*

RediHeat

Cold Water

Supply

Hot

Water To

Users

Diverting Valve

(Fixed Thermostat)

*

RediHeat

Cold Water

Supply

Hot

Water To

Users

* A Thermal expansion tank may be required when the cold

water inlets include check valves.

* A Thermal expansion tank may be required when the cold

water inlets include check valves.