3

7

1.13 Residual hazards

In normal use the external surface of the product

may be very hot. If used at the maximum

permitted operating conditions the surface

temperature of some products may reach

temperatures in excess of 300°C (572°F).

Many products are not self-draining. Take due

care when dismantling or removing the product

from an installation (refer to 'Maintenance

instructions').

1.14 Freezing

Provision must be made to protect products

which are not self-draining against frost

damage in environments where they may be

exposed to temperatures below freezing point.

1.15 Disposal

Unless otherwise stated in the Installation

and Maintenance Instructions, this product

is recyclable and no ecological hazard is

anticipated with its disposal providing due

care is taken.

1.16 Returning products

Customers and stockists are reminded that

under EC Health, Safety and Environment Law,

when returning products to Spirax Sarco they

must provide information on any hazards and

the precautions to be taken due to contamination

residues or mechanical damage which may

present a health, safety or environmental risk.

This information must be provided in writing

including Health and Safety data sheets relating

to any substances identified as hazardous or

potentially hazardous.

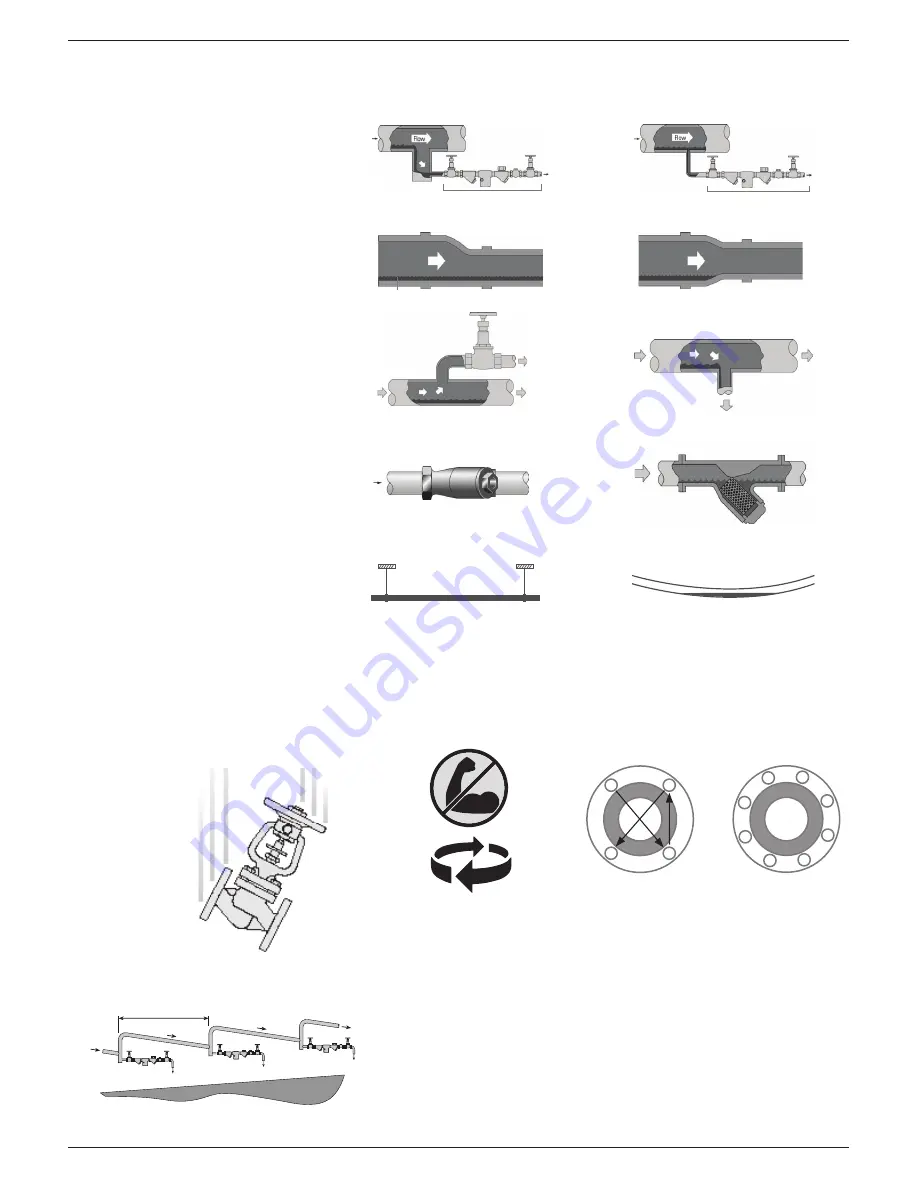

1.17 Working safely with cast iron

products on steam

Cast iron products are commonly found on

steam and condensate systems. If installed

correctly using good steam engineering

practices, it is perfectly safe. However, because

of its mechanical properties, it is less forgiving

compared to other materials such as SG iron or

carbon steel. The following are the good

engineering practices required to prevent

waterhammer and ensure safe working

conditions on a steam system.

Cast Iron is a brittle

material. If the product

is dropped during

installation and there

is any risk of damage

the product should

not be used unless it

is fully inspected and

pressure tested by the

manufacturer.

Safe Handling

Steam

Trap set

Trap set

Trap set

Steam

Gradient 1:100

Gradient 1:100

30 - 50 metre intervals

Condensate

Condensate

Condensate

Prevention of water hammer

Steam trapping on steam mains:

Steam Mains - Do's and Dont's:

Steam

4

7

7

7

7

4

4

4

Prevention of tensile stressing

Pipe misalignment:

Installing products or re-assembling after maintenance:

Do not over tighten.

Use correct torque figures.

1

1

4

2

3

8

2

6

3

7

Flange bolts should be gradually tightened across

diameters to ensure even load and alignment.

7

4

5

4