8

install lower diaphragm case (5) securing it with cap

screws (14) tightening in a sequential manner (note

location of notch in relation to valve body).

7. Install adjustor key cylinder (25) on the pin located on

the valve shaft. Replace O-ring on temperature control

rod (18) and insert so adjustor key is centered in slot

and notch on control rod fits with groove pin in adjusting

sleeve (27). Install circlip (23) and locking ring (21).

8. Install, in order, the control valve spring (10), spring

guide washer (16), diaphragm plate (11), diaphragm

(13), O-ring (9), shouldered washer (8), and jam nuts (7),

on main valve stem. Position diaphragm over holes and

notch on lower case prior to tightening the jam nuts.

9. Install upper cover (6) and be sure notches in lower

cover, diaphragm and upper cover line up. Install bolts

and tighten sequentially.

10. Install valve on frame.

11. Install sensing tube (46) and Victaulic fittings. Check all

fittings for tightness.

12.

Refer to start-up procedures for temperature

adjustment.

3.3 Heat Exchanger Inspection Disassembly

The heat exchanger coil is readily accessible for inspection

and cleaning without disturbing the steam or water piping.

Procedure

1. Remove plug to drain the casing.

2. Remove all base plate nuts (93 or 94).

3. Lift off the casing (80 or 81), being careful not to damage

the gasket (84 or 85).

4. If a leak in the tubing is suspected, water pressure can

be turned on. Any leaks should be easily seen with the

unit still in place.

To Clean the Coil

Depending on local water conditions, scale deposits from

hard water can form inside the heat exchanger coil. The

coil can be cleaned in place using an acid pump cleaning

system employing the following procedure:

1. Remove the two cast bronze elbow manifolds from

the heat exchanger by disassembling the four Victaulic

couplings.

2. Attach the 3/8” nipple supplied with the acid cleaning

system adaptor kit to one of the adaptors.

3. Insert this adaptor into the heater connection closest to

the center of the exchanger.

Note:

the 3/8” nipple must extend up into the exchanger.

4. Secure the adaptor with one of the Victaulic couplings

removed in Step 1.

5. Connect the other adaptor to the remaining exchanger

connection with a Victaulic coupling.

6. Connect the acid hoses, pump and reservoir.

7. For proper cleaning, the acid must be pumped through

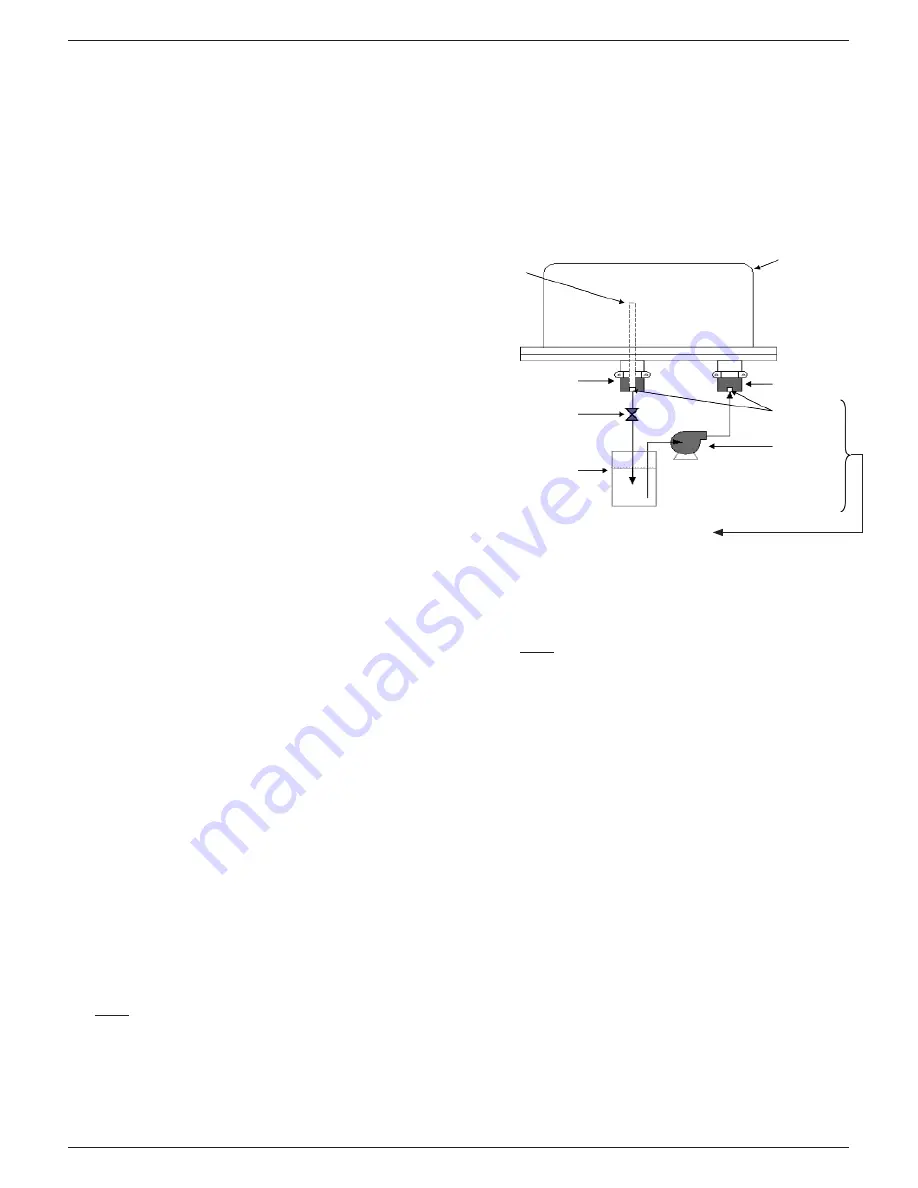

the exchanger in the direction shown in Fig 1 below.

The 3/8” nipple avoids gas pockets in the top of the

exchanger coil and must be on the outlet connection of

the cleaning system.

3/8” nipple must

be on return line

to acid reservoir

Heat Exchanger

Outlet

adaptor

3/8” or 1/2”

Globe Valve

Acid reservoir:

Oakite #32 or

similar acid

Intlet

adaptor

3/8” pipe

connections

Acid pump:

Jabasco,

Little Giant,

Calgon

or similar

Furnished

by customer

8. After cleaning is complete, the coil should be flushed

with water before reconnecting the manifolds.

Note:

For acid preparation, cleaning and safety

procedures, refer to the instructions supplied by the

acid manufacturer.

If Removal of the Coil is Necessary

1. Disconnect water piping and remove the manifold nuts

and lock rings.

2. Lift off the coil assembly (78 or 79), being careful not to

damage the manifold gaskets.

3.4 Re-assembly

Procedure

1. Replace manifold and baseplate gaskets.

2. Check that the tabs on the manifold lock rings fit into

the base plate slots. These keep the manifold-coil

assembly from turning when tightening the manifold

nuts.

3. Be sure the bottoms of the manifolds are seated in

pockets located inside the casing.

4. Install and tighten manifold nuts.

5. Install casing and tighten bolts sequentially.

6. Check nuts for tightness after an hour or two and again

after 24 hours of operation.

FIG. 1