IM-P192-02

MI Issue 2

16

Upstream / downstream pipework

The TVA flowmeter should be installed in pipework manufactured to BS 1600, ASME B 36.10

Schedule 40 or EN 10216-2 / EN 10216-5 equivalent, which corresponds to the following

pipeline internal diameters:

For different pipe standards / schedules,

if the flowmeter is being operated at the

extreme of its published maximum

range, and maximum accuracy is

required, downstream spool pieces

manufactured from pipe to the above

standard should be used.

It is important that the internal upstream and downstream diameters of pipe are smooth.

Ideally seamless pipes should be used and there should be no intrusive weld beads on the

internal diameter. It is recommended that slip-on flanges be used to avoid any intrusive weld

beads on the internal diameter of the pipe.

Note:

See Figures 11 to 14 for other considerations which need to be noted before

determining the correct installation location.

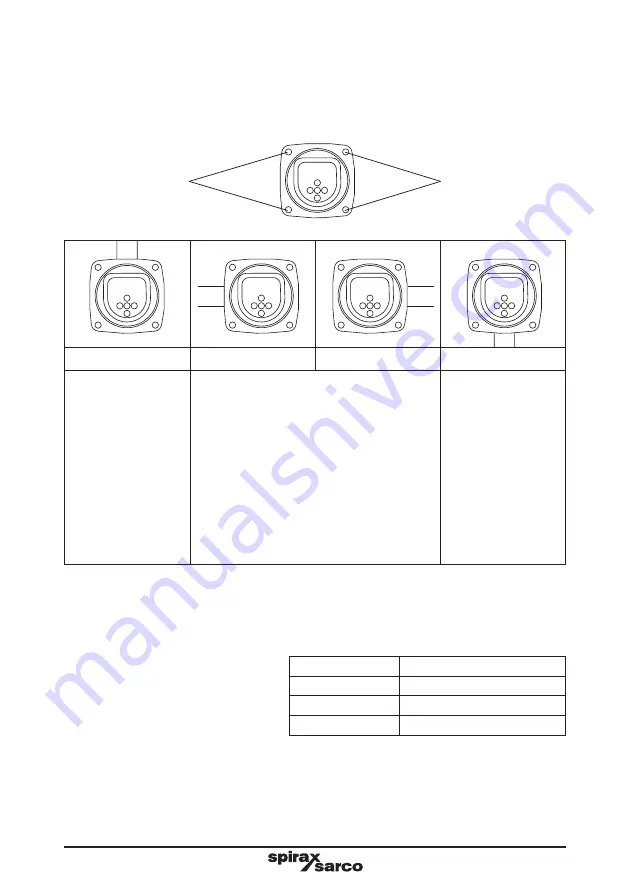

Rotating the electronics front panel

To rotate the electronics front panel loosen the four retaining screws and rotate the front

panel to the orientation, required.

Note:

Take care not to damage or strain any of the wiring.

A

B

C

D

For applications with

steam above 7 bar g

and all superheated

applications.

Note:

Fit ting the T VA

in this orientation

when the RS485

b o a r d i s f i t t e d

ensures that the

display can be read

easily.

For vertical flow applications.

For saturated steam

applications below

7 bar g.

Retaining screws

Retaining screws

Nominal diameter Nominal internal diameter

50 mm

52 mm

80 mm

77 mm

100 mm

102 mm