Customer service 1-888-707-1880

Dyaco Canada Inc 2013.

Email: customerservice@dyaco.ca

41

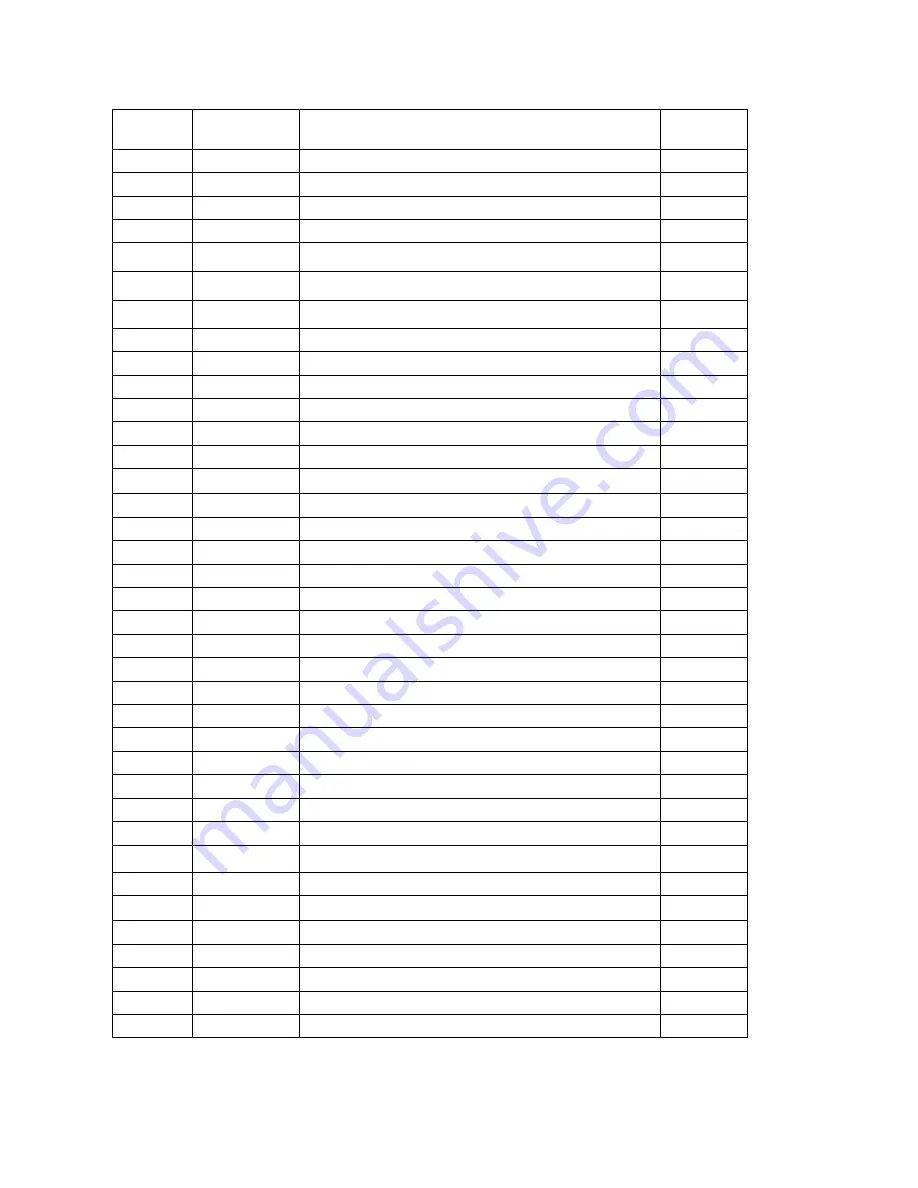

KEY NO

PART NO DESCRIPTION

QTY

42

1660542

Handgrip Side Cap(Top)

2

43

1660543

Handgrip Side Cap (Bottom)

2

44

1660544

Hall Sensor Rack

1

45

1660545

Pedal

(

L

)

1

46

1660546

Pedal

(

R

)

1

47

1660547

Transportation Wheel

2

49

1660549

1"_Button Head Plug

4

50

1660550

3/8" × 2-1/4"_Hex Head Bolt

4

51

1660551

5/16" × 5/8"_Hex Head Bolt

9

52

1660552

5 × 19m/m_Tapping Screw

2

53

1660553

5/16" × 1-3/4"_Button Head Socket Bolt

2

54

1660554

1/4" × 3/4"_Hex Head Bolt

8

55

1660555

M8 × 170m/m_J Bolt

1

56

1660556

M6 × 15m/m_Phillips Head Screw

3

57

1660557

3/16" × 15 × 1.5T_Flat Washer

1

58

1660558

M5 × 12m/m_Phillips Head Screw

12

59

1660559

3/8" × 2m/m_Flat Head Socket Bolt

4

61

1660561

5 × 16m/m_Tapping Screw

6

62

1660562

Ø3 × 20m/m_Tapping Screw

4

63

1660563

Ø3.5 × 16m/m_Sheet Metal Screw

7

64

1660564

Ø3.5 × 20m/m_Sheet Metal Screw

1

65

1660565

Ø3 × 10m/m_Tapping Screw

4

66

1660566

Ø17_C Ring

1

67

1660567

Ø20_C Ring

2

69

1660569

1/4" × 13 × 1T_Flat Washer

7

70

1660570

3/8" × 19 × 1.5T_Flat Washer

4

71

1660571

3/8" × 25mm × 2.0T_Flat Washer

5

72

1660572

5/16" × 18mm × 1.5T_Flat Washer

9

73

1660573

Ø17 × 23.5 × 1T_Flat Washer

1

76

1660576

Ø1/4"_Split Washer

7

77

1660577

M8 × 7T_Nyloc Nut

1

78

1660578

3/8" × 7T_Cap Nut

1

79

1660579

1/4" × 8T_Nyloc Nut

4

80

1660580

5/16" × 6T_Nyloc Nut

4

82

1660582

3/8" × 7T_Nut

8

83

1660583

M10 × 1.25_ Nut

2

85

1660585

Round Disk

2