CUSTOMER SERVICE 1-888-707-1880

17

Dyaco Canada Inc. ©2013

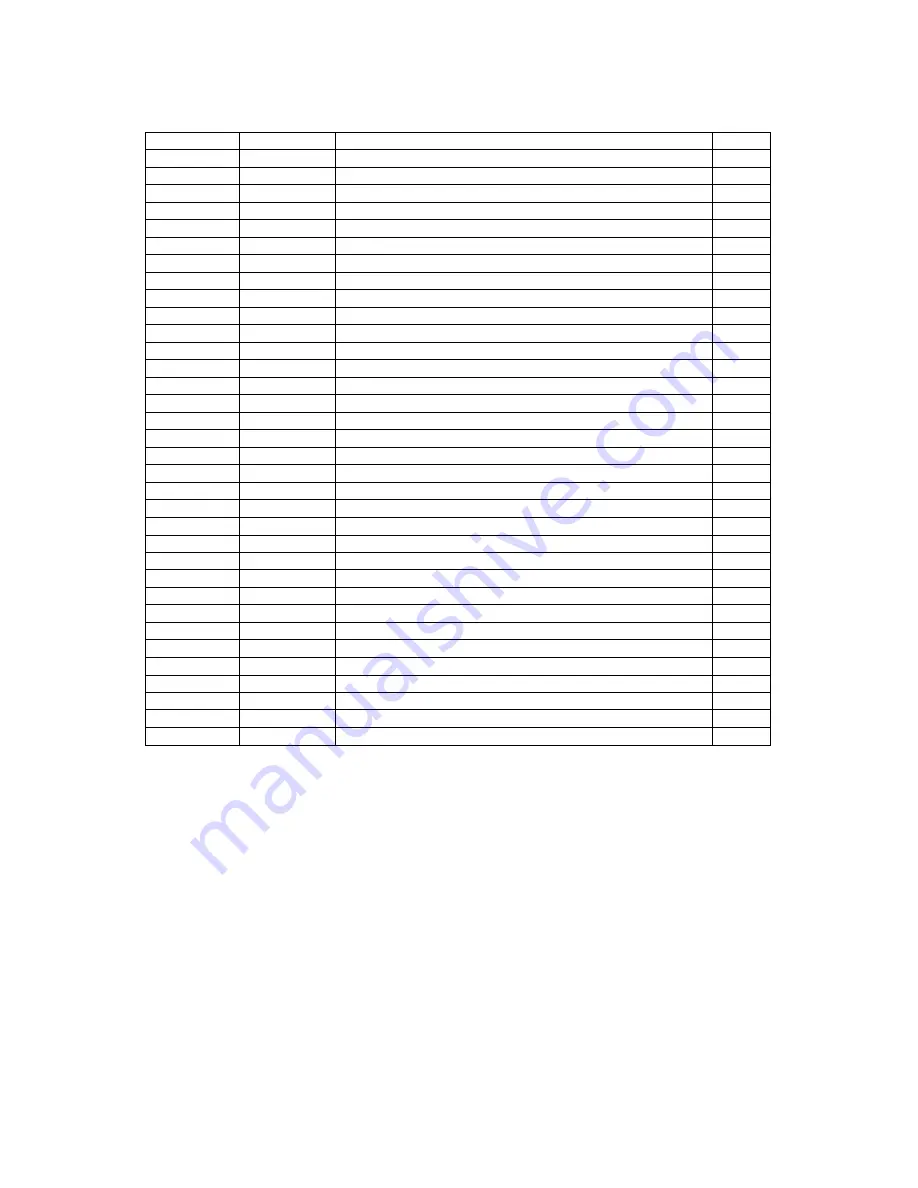

KEY NO.

PART NO.

DESCRIPTION

Q'TY

101

17680101 Emergency Brake Cable

1

102

17680102 Sliding Wheel (PU 72mm dia )

4

103

17680103 Brake Return Spring (52 x 3.5 x 50L)

1

104

17680104 Brake Magnet N35 ( 25 x 10L )

2

105

17680105

Sweat Tube Retainers

4

106

17680106

Ø1/4 × 1.5-450m/m_Drainage Tube, PVC

2

110

17680110 Nyloc Nut M10 - 8t

2

111

17680111 Tapping Screw M4 x 12mm, Black

6

113

17680113 Ø5 × Ø10 ×1.0T_Flat washer

4

115

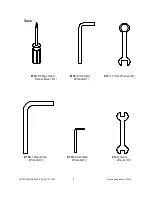

17680115 Phillips HeadScrew Driver

1

116

17680116 8th L Allen Wrench

1

117

17680117 17m/m_Wrench

1

118

17680118 12th L Allen Wrench

1

119

17680119 5th L Allen Wrench

1

120

17680120 13.14m/m_Wrench

1

121

17680121 Flywheel Set Collar ( L )

1

122

17680122 Flywheel Set Collar ( R )

1

124

17680124 Idler Wheel

2

127

17680127 Ø35_C Ring

2

128

17680128 Socket Head Cap Bolt M10 x 1.5 - 80mm

1

129

17680129

Socket Head Cap Bolt M10 x 1.5 - 25mm (Stainless steel)

4

131

17680131 Flywheel

1

132

17680132 Ø174_Pulley

2

133

17680133 Drive Axle

1

134

17680134 Ø60_Pulley

1

135

17680135 Axle for Idler Wheel (L)

1

136

17680136 Axle for Idler Wheel (R)

1

137

17680137 Ø8 × 35 × 3.0T_Flat Washer

1

138

17680138 Poly-V Belt, 6PK 1000mm

2

139

17680139

6 × 6 × 20L_Twin Circle Key

1

140

17680140

TPR Handle Bar Axle Inner Cover

2

141

17680141

M8-10m/m_Slotted Set Screw

1

142

17680142

M8 × 1.25-15m/m_Socket Head Cap Bolt

1

143

17680143

M10 × 1. 5 - 20m/m_Socket Head Cap Bolt

2