IN839

12

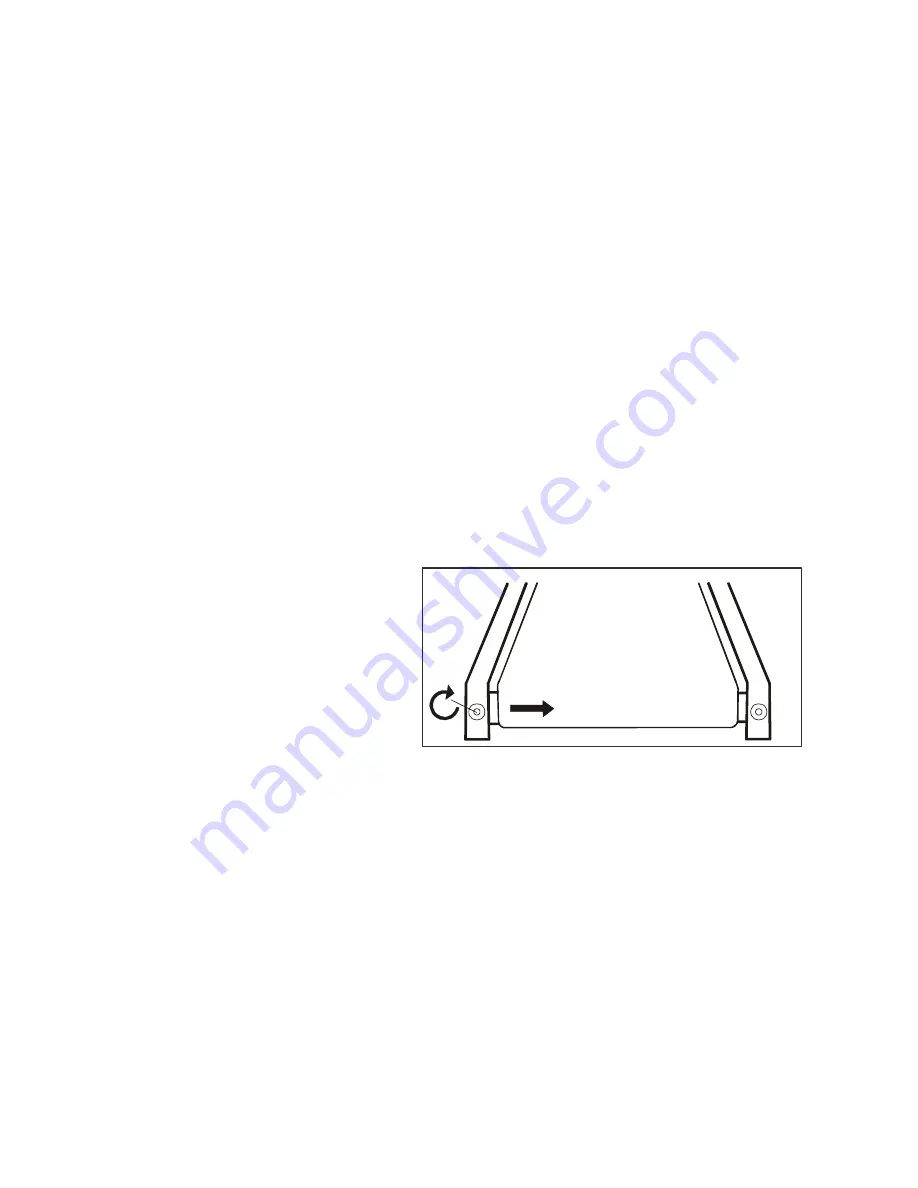

Tighten the rear roller only enough to prevent slippage at the front roller. Turn the

treadbelt tension adjusting bolt in increments of 1/4 turn and inspect for proper tension.

When an adjustment is made to the belt tension, you must also make a tracking

adjustment to compensate for the change in belt tension.

This is accomplished by

turning both the tension and tracking Allen bolts an equal amount. This adjustment

should be made by turning both bolts clockwise by no more than a 1/4 turn at a time.

DO NOT OVERTIGHTEN

– Over tightening will cause belt damage and premature

bearing failure.

TREADBELT TRACKING ADJUSTMENT:

The performance of your treadmill is dependent on the frame running on a reasonably

level surface. If the frame is not level, the front and back roller cannot run parallel, and

constant belt adjustment may be necessary.

The treadmill is designed to keep the treadbelt reasonably centered while in use. It is

normal for some belts to drift near one side while the belt is running with no one on it.

After a few minutes of use, the treadbelt should have a tendency to center itself. If,

during use, the belt continues to move toward one side, adjustments are necessary.

TO SET TREADBELT TRACKING:

A 6 mm Allen wrench is provided to adjust the rear roller. Make tracking adjustments

from the left

side only. Set belt

speed at approximately 2 to 3 mph.

A small adjustment can make a

dramatic difference. Turn the bolt

only a 1/4 turn and wait a few

minutes for the belt to adjust itself.

Continue to make 1/4 turns until the

belt stabilizes in the center of the

running deck. The belt may require

periodic tracking adjustment

depending on use and

walking/running characteristics. Some users will affect tracking differently. Expect to

make adjustments as required to center the treadbelt. Adjustments will become less of a

maintenance concern as the belt is used. Proper belt tracking is an owner responsibility

common with all treadmills.

ATTENTION:

DAMAGE TO THE RUNNING BELT RESULTING FROM IMPROPER TRACKING /

TENSION ADJUSTMENTS IS NOT COVERED UNDER THE SPIRIT WARRANTY.

BELT / DECK LUBRICATION:

Do not re-lube with other than Spirit lubricant. Spirit provides one application with this

unit. See your Spirit dealer for additional purchases. The use of some other lubricants

may destroy the deck surface or belt and will void warranty. Conditions exist beyond

Spirit’s control on belt / deck cleanliness which relates to friction.

You should apply the enclosed belt lubrication after approximately the first 50 hours of

operation. Use all the contents of one container (no more) and spread lubricant onto