10

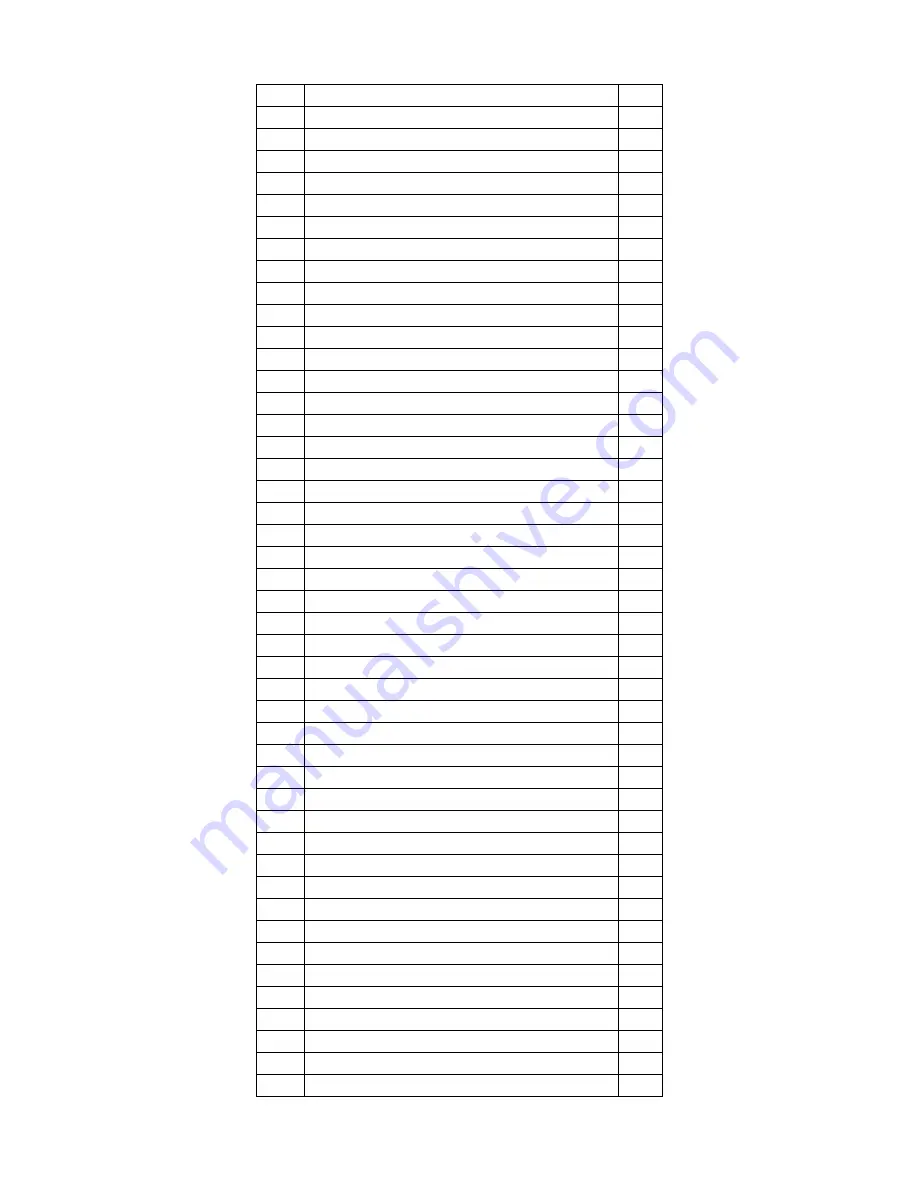

Parts list

NO.

DESCRIPTION

O'TY

1

Main Frame

1

2

Console Mast

1

3

Sliding Pedal Arm (R)

1

4

Sliding Pedal Arm (L)

1

5

Connecting Pedal Arm (R)

1

6

Connecting Pedal Arm (L)

1

7

Main Crank Axle

1

8

Swing Arm (R)

1

9

Swing Arm (L)

1

10

Crank Arm

2

11

Flywheel

1

11-1

Nylon Round Disk

2

12

Ø174 Main Pulley

1

13

Ø174 Drive Pulley

1

14

Drive Axle

1

15

Pulley

1

16

Axle for Idler Wheel (L)

1

17

Axle for Idler Wheel (R)

1

18

Bearing Housing, Crank Axle

2

19

Side Case bracket

2

20

Set Collar

1

21

Brake Magnet Mounting Arm

1

22

Tension Cable Retainers

2

23

Brake Mounting Bracket

1

24

Cup Washer For M8 Bolt

6

25

Bearing ( 6005 )

6

26

Bearing ( 6003 )

24

27

Rod End Bearing

2

28

Aluminum Track

4

29

C Ring 17mm dia

6

30

C Ring 25mm dia

5

31

Wave Washer 17mm dia

12

32

Nyloc Nut M6 - 6t

1

33

Nyloc Nut M8 - 7t

2

34

Nyloc Nut 5/16" - 7t

2

35

Socket Head Cap Bolt M5 × 0.8 - 12mm

4

36

Socket Head Cap Bolt M5 × 0.8 - 20mm

1

37

Socket Head Cap Bolt M6 × 1.0 - 15mm

8

38

Socket Head Cap Bolt M6 × 1.0 - 50mm

1

39

Socket Head Cap Bolt M8 × 1.25 - 12mm

6

40

Socket Head Cap Bolt M8 × 1.25 - 15mm

7

41

Socket Head Cap Bolt M8 × 1.25 - 35mm

2

42

Socket Head Cap Bolt M10 × 1.5 - 20mm

4

43

Socket Head Cap Bolt M10 × 1.5-80 mm

1

44

Button Head Socket Bolt 5/16" × 1-3/4"

2

Summary of Contents for SE500

Page 1: ...SERVICE MANUAL SE500 ...