Super Shred 3

Operation

Owners Manual

16

If after years of operation jamming is occurring under

exceptionally light loads, the wear parts pay need to be

replaced. Shredder rotors and scraper bars are a wearable item.

If this occurs read (Page 20, Wear parts). These items need to

be inspected. If they are worn and replacements are needed,

call technical support.

5. Shredder is not pulling in material / pulling too much material

- The shredder teeth are designed to pull in material, however

there are scenarios that could cause issue.

The material is not feeding from the top hopper into the shredder

teeth. This will occur when the hopper is filled to full and the

material “stacks” in the hopper and does not feed properly. To

reduce this issue, remove material from the hopper, and fill the

hopper to a lower level. Also, if “stacking” is occurring, it is

important to not pack or compact the material in the top hopper

before the lid is closed and the shredder is started.

The shredder is pulling to much material and is constantly tripping

the breaker. This usually occurs when stringy / stem material is

being shredded. Due to the stringy nature of the material, once the

shredding teeth engage the material, it continues to pull more

material into the shredder. This can be solved by loading less

material into the top hopper. To maintain shredding production, a

mix of stringy stems and leaves can be mixed to reduce

feeding/overloading issues.

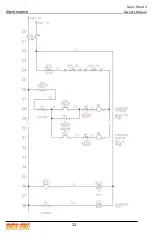

6. Emergency Stop light is ON

- The Emergency switch will illuminate when the shredder is in

emergency stop mode. To place the Super Shred 3 in operation

mode, pull and twist the emergency stop lightly. This will allow it

to “pop out” into operation mode. If the red light remains ON, an

electrical fault within the safety circuit is being observed.

Request a technician for observation or call technical support at

Split-fire for assistance.