7

Boats with Aluminum Floor

1.

Identifying numbers on floor boards must face upwards.

2.

Insert floor board #1 in bow of boat.

3.

Insert floor board #4 in transom of boat.

4.

Insert floor board #2 into floor board #1.

5.

Insert floor board #3 into floor boards

#2 and #4 and press down until flat.

Side joiner Assembly

1.

once the tube is 50% inflated, use an oar (a) to prop up the bottom to raise the floor

boards (b) about 1-2 inches off the flat surface. Attach side joiners (c). Repeat the

procedure on opposite side of the boat. If you

have more than one joiner on each side, start

with one long, one short joiner on one side and

with one short and one long on the other side.

(asymmetric)

2.

finish inflating the tube one after the other in

order to maintain equal amount of air. Do not

fully inflate any chamber at one time. Make sure

the tube is 100% inflated and firm. An under

inflated tube will cause the boat to not work properly and could potentially

damage the product and cause injury risk.

3.

Inflate the keel and close valve caps. Close valve properly by making sure the spring

inside is popped completely out. no air should be coming out of the valve before

placing the cap back on.

Your Inflatable Sport Boat is ready to go!

7

Step by step Assembly:

1.

Remove the boat from the box and lay it out on a clean flat surface with no

sharp objects. Make sure the boat is completely spread out with nothing on it

or below it before assembly.

2.

Remove the valve cover and use a boat inflator to inflate the PVC tubes to about

50% capacity. We personally recommend using a vacuum with blow function or

a Metro Vac Inflator found at

www.inflatablesportboats.com

.

*DO NOT INFLATE THE KEEL UNTIL FLOOR BOARDS HAVE BEEN INSTALLED*

Boats with Inflatable Air Floor

1.

Unfold and stretch out the floor onto the bottom of the boat, edging it under

the half-inflated tubes and against the transom. The valve must face upwards.

2.

Inflate the floor up to 75%.

3.

Finish inflating the boat.

4.

Finish inflating the floor.

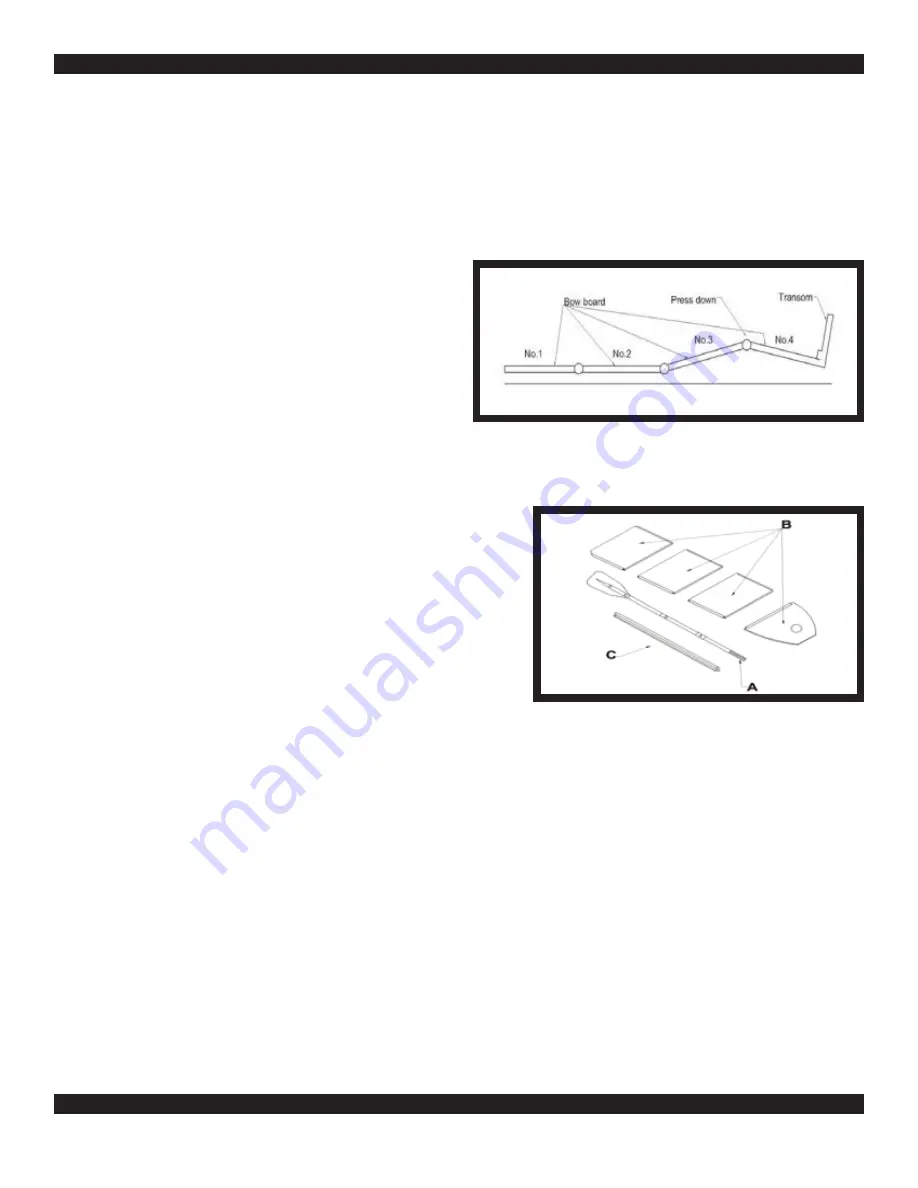

Boats with Aluminum Floor

1.

Identifying numbers on floor boards must face upwards.

2.

Insert floor board #1 in bow of boat.

3.

Insert floor board #4 in transom of boat.

4.

Insert floor board #2 into floor board #1.

5.

Insert floor board #3 into floor boards #2 and #4 and press down until flat.

8

Side Joiner Assembly

1.

Once the tube is 50% inflated, use an oar (a) to prop up the bottom to raise

the floor boards (b) about 1-2 inches off the flat surface. Attach side joiners

(c). Repeat the procedure on opposite side of the boat. In case of more than

one joiner on each side, start with one long, one short joiner on one side and

with one short and one long on the other side. (asymmetric)

3.

Finish inflating the tube one after the other in order to maintain equal

amount of air. Do not inflate any chamber completely full at one time. Make

sure the tube is 100% inflated and firm. An under inflated tube will cause the

boat to not work properly and could potentially damage the product and

cause injury risk.

4.

Inflate the keel and close valve caps. Close valve properly by making sure the

spring inside is popped completely out. No air should be coming out of the

valve before placing the cap back on.

Your Inflatable Sport Boat is ready to go!

Step by step Disassembly and Storage:

1.

Follow step #1 in assembly.

2.

Wipe down product completely before deflating. It is easier to clean while

inflated. IMPORTANT: storing a wet product can cause mildew, mold, and can

damage the product.

3.

Lift and remove one of the middle floorboards first. Remove bow and

transom boards last. Place floorboards, side joiners, and oars in carry bag.

4.

Use an inflator on “sucking function” to remove excess air from each

chamber.

5.

Fold each side of the boat into the middle. Go to the bow and roll up like a

sleeping bag and place in bag.

Cleaning your Boat:

Sport Boats are manufactured with a heavy duty 1100 denier weather resistant UV

protected PVC material. The PVC material doesn’t require any special type of