Troubleshooting

Model: T611

Malfunction: SERVICE REQUIRED TREADMILL SHUTTING DOWN STOPPING

Circumstance: Display shows “SERVICE REQUIRED TREADMILL SHUTTING DOWN STOPPING”, the motor overheat error.

Possible cause: 1. Motor is excessively hot; overheat protective circuit

operates.

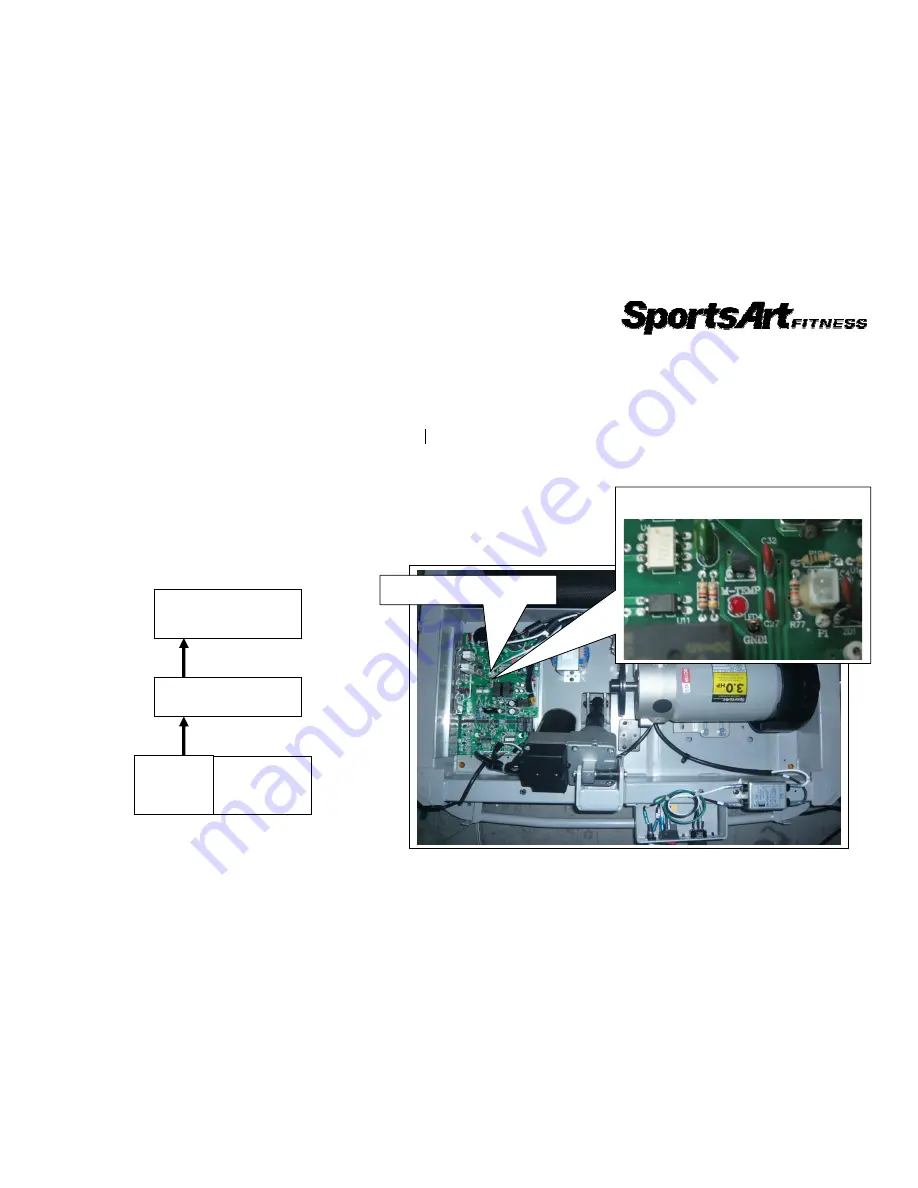

Troubleshooting: 1. Inspect the motor thermal switch and fold-up switch

cable connections. (These two cables are connected.)

2. Inspect the motor cover. Is it hot?

3. If it is hot and the unit has been in use for a long period of time,

the motor overheat protective function is operating. Turn off the unit.

Let it sit without use for half an hour.

4. If ERR14 often appears, please lubricate the walk belt and deck.

If the belt is worn, replace it.

5. If replacing the walk belt does not remedy the situation, the motor

is suspect.

3-13-1

Drive board

Display board

Thermal

switch

Motor

Motor thermal switch cable

M-TEMP LED

Summary of Contents for T611

Page 1: ...T611 Repair Manual Electronics...

Page 4: ...1 1 Product Picture T611 1 1 1...

Page 5: ...1 2 Overlay T611 1 2 1...

Page 7: ...1 3 Connections T611 Bridge Board 1 3 2 To Safety key board HTR board Soft key Bridge board...

Page 11: ...1 5 Connections T611 Bridge Board 1 5 2 To Safetykey board To HTR board To Display...