27

7.

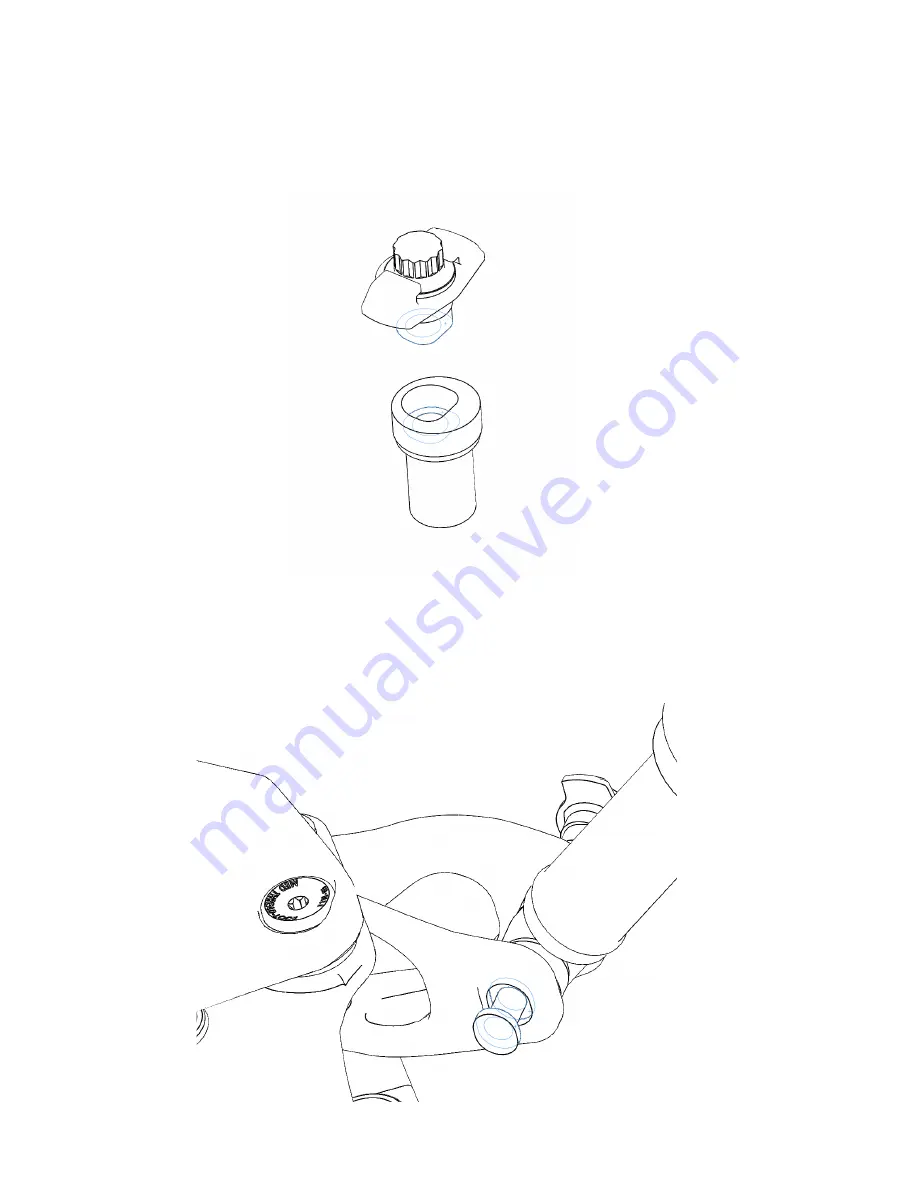

Shock installation is the reverse of removal. Begin by installing the shock with rear eyelet hardware

into the yoke. It is important to observe the orientation of the adjuster cap and eyelet reducer as the

two parts are keyed and will only assemble if aligned properly:

Similarly, the shock pin is keyed into an oval recess in the lower jaw of the shock yoke. Ensure

alignment as the pin is inserted:

Summary of Contents for Mayhem 130

Page 1: ...1 MY21 Mayhem 130 Frames Assembly Instructions and Maintenance Manual ...

Page 9: ...9 2 Use the open end of the wrench to turn the adjuster cap 180 Either direction will work ...

Page 54: ...54 Mayhem 130 150 Frame Parts Reference ...