ProSpray 3.20

15

GB

Repairs at the unit

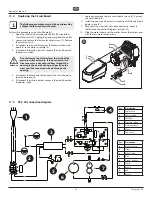

11.6 Replacing the Pressure Switch / Transducer

i

The following procedure must only be performed by

a Wagner Authorized Service Center.

i

If the sprayer loses all pressure adjustment, or there

is paint leakage from the front of the sprayer, the

pressure switch and/or transducer may need to be

replaced.

1. Open the relief valve, valve position PRIME (

k

circulation).

Switch the unit OFF. Unplug the power plug from the outlet.

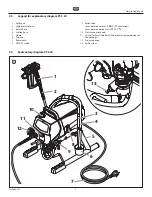

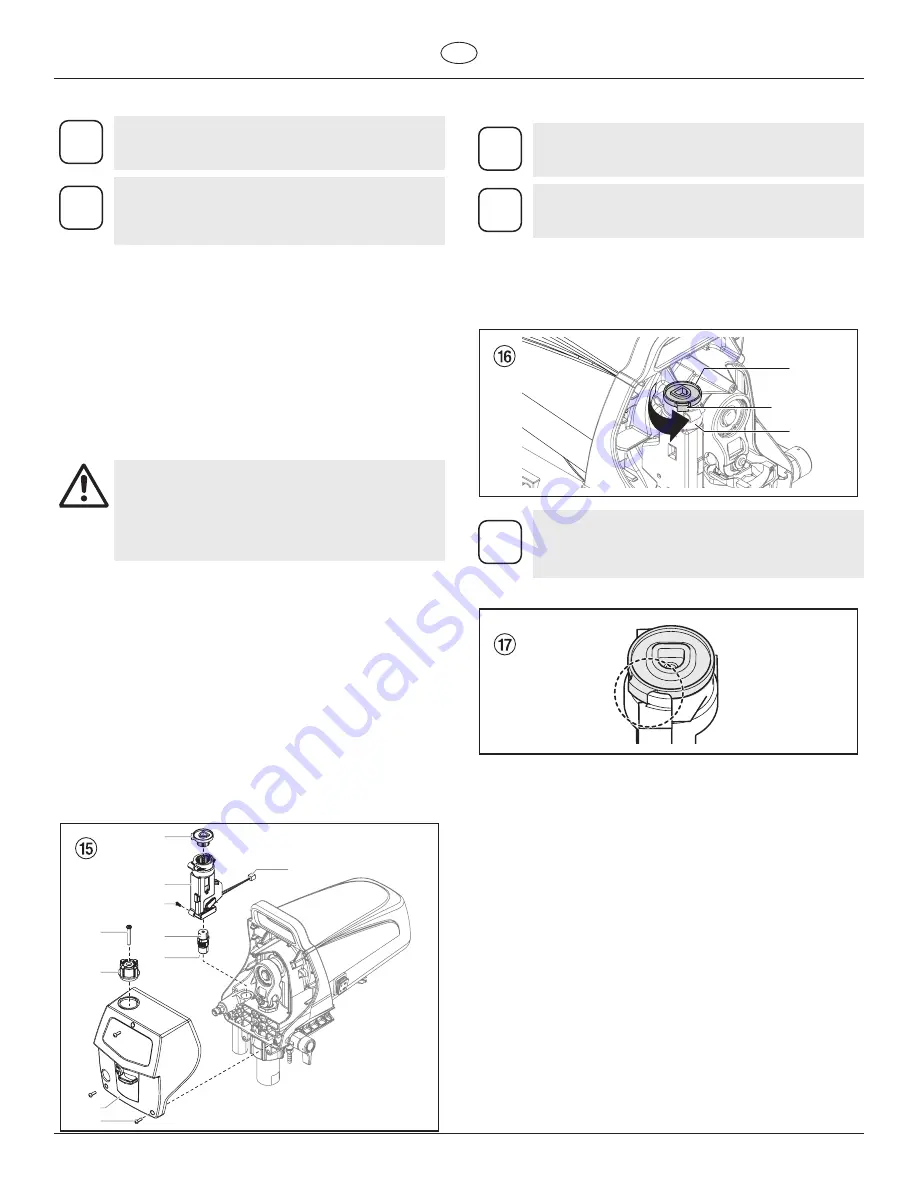

2. Remove the screw (1) that secures the pressure control knob

(2) to the bottom of the pressure control knob (3). Remove

the knob (2).

3. Loosen and remove the three front cover screws (4). Remove

the front cover (5).

4. Remove the screw (7) from the side of the pressure switch.

Remove the bottom of the pressure control knob (3) from the

top of the pressure switch.

5. Remove the pressure switch assembly (6) from the top of the

transducer (8).

6. Unplug the pressure switch (6) from the wire connector (10).

Attention

Do not attempt to pull wires from the inside of the

pressure switch assembly. If the pressure switch

wire connector (10) is not exposed from through

the opening in the pump housing, pull gently on

the wires until the connector is shown through the

opening.

7. Check pressure switch continuity at the connector. If the

switch is bad replace with a new pressure switch assembly.

8. Inspect the transducer (8) for the presence of paint. If there is

paint, replace the transducer. If there is no paint, skip to step

9, below.

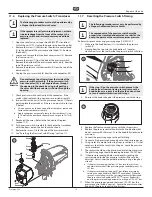

a. Using a wrench on the hex head of the transducer, loosen and

remove the transducer assembly.

b. Apply a generous amount of grease to the transducer O-ring

(9). Reinstall the transducer assembly and torque to 70-75 in/

lbs.

9. Reconnect the wires (Refer to the Connection Diagram,

section 11.9).

10. Push pressure switch assembly (6) back onto the transducer

until it bottoms out on the transducer hex head.

11. Replace the screw (7) into the side of the pressure switch.

12. See “Resetting the Pressure Switch Timing”, section 11.7.

1

3

6

8

10

9

7

2

5

4

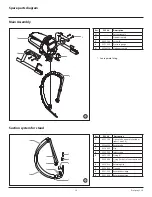

11.7 Resetting the Pressure Switch Timing

i

The following procedure must only be performed by

a Wagner Authorized Service Center.

i

The components of the pressure switch must be

properly reassembled and adjusted in order for the

pump to operate at the correct maximum pressure.

Perform this procedure using pressure gauge P/N 0521229.

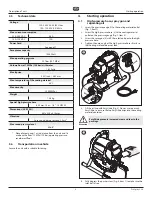

1. Make sure the knob bottom (1) is installed in the pressure

switch (2).

2. Viewing from the top, turn the knob bottom (1) counter-

clockwise as far as the teeth inside the pressure switch will allow.

1

3

2

i

If the stop (3) on the pressure switch prevents the

knob bottom from continuing to turn, remove the

knob bottom, re-orient it on the teeth and continue

to turn it counterclockwise until it stops.

3. Re-orient the knob tab against the pressure switch tab stop.

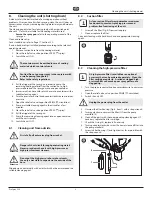

4. Replace the front cover and secure with the three screws.

5. Replace the pressure control knob into the knob bottom but

do not secure with the screw. Turn the knob fully clockwise to

maximum.

6. Connect the pressure gauge to the outlet fitting.

7. Connect a high-pressure hose and gun to the pressure gauge.

8. Using water as a media, follow the steps in section 4.4. It is not

necessary to attach a spray tip to the gun. Leave the pressure

set to maximum.

9. The sprayer should now be pressurized at maximum pressure.

The pressure gauge should be reading between 193-207 bar.

10. If the pressure reading is below or above this reading, the

set screw down inside the pressure switch will have to be

adjusted. Adjust it per the guidelines below using a long hex

wrench.

a. If the pressure reading is below 193 bar, turn the set screw

counterclockwise until the pressure gauge reads between 193-

207 bar.

b. If the pressure reading is above 207 bar, relieve pressure by

turning the valve handle to PRIME (

k

circulation). While the

sprayer is circulating, turn the set screw clockwise slightly and

then turn the valve handle to SPRAY (

p

spray). Repeat this

until the pressure reading decreases to a range of 193-207 bar.

11. When the pressure gauge reads between 193-207 bar, the

pressure control knob is now set. Secure the pressure control

knob with the pressure control knob screw.