4.4

Taking the unit into operation with coating

material

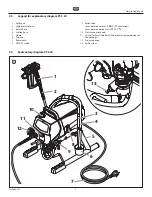

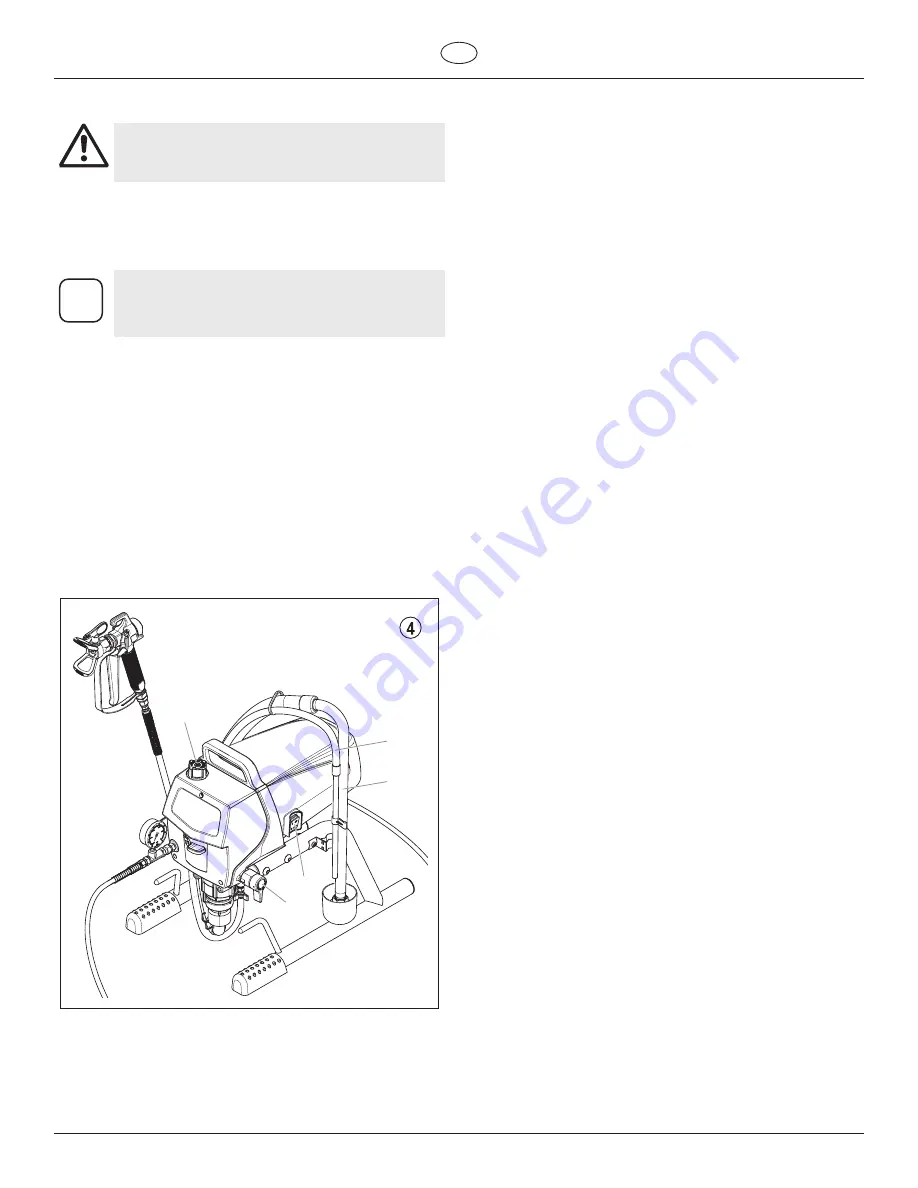

1. Immerse the suction tube (Fig. 4, Item 2) and return hose (1)

into the coating material container.

2. Turn the pressure control knob counterclockwise (3) to

minimum pressure.

3. Open the relief valve (4), valve position PRIME (

k

circulation).

4. Switch the unit (5) ON.

5. Wait until the coating material exudes from the return hose.

6. Close the relief valve, valve position SPRAY (

p

spray).

7. Trigger the spray gun several times and spray into a collecting

container until the coating material exits the spray gun

without interruption.

8. Increase the pressure by slowly turning up the pressure

control knob.

Check the spray pattern and increase the pressure until the

atomization is correct.

Always turn the pressure control knob to the lowest setting

with good atomization.

9. The unit is ready to spray.

ProSpray 3.20

7

GB

Starting operation

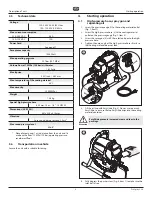

4.2

Connection to the mains network

Attention

The unit must be connected to an appropriately-

grounded safety outlet.

Before connecting the unit to the mains supply, ensure that the line

voltage matches that specified on the unit’s rating plate.

The connection must be equipped with a residual current protective

device with INF ≤ 30 mA.

i

Spray Centre‘s accessories program also includes a

mobile operator protection device for the electronic

supply, which can also be used with other electronic

equipment.

4.3

Cleaning preserving agent when starting-up

of operation initially

1. Immerse the suction tube (Fig. 4, Item 2) return hose (1) into a

container with a suitable cleaning agent.

2. Turn the pressure control knob counterclockwise (3) to

minimum pressure.

3. Open the relief valve (4), valve position PRIME (

k

circulation).

4. Switch the unit (5) ON.

5. Wait until the cleaning agent exudes from the return hose.

6. Close the relief valve, valve position SPRAY (

p

spray).

7. Pull the trigger of the spray gun.

8. Spray the cleaning agent from the unit into an open collecting

container.

3

1

2

4

5