AA

19

0D

AG

Se

ries

Air

Motor

‐

Driven

Tank

Washer

|

1

1/

1

1/

20

10

|

RE

V

.

1

14

MAINTENANCE

IT IS YOUR RESPONSIBILITY TO REGULARLY INSPECT AND MAKE NECESSARY REPAIRS

TO THIS PRODUCT IN ORDER TO MAINTAIN PROPER OPERATION.

IT IS RECOMMENDED

THAT THE BUSHINGS AND SEALS BE INSPECTED EVERY 1000 HOURS OF OPERATION OR

SOONER IF EXCESSIVE LEAKAGE OF THE SEALS OCCURS.

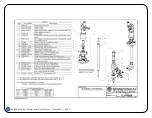

REMOVAL AND REPLACEMENT OF SPRAY NOZZLES (ITEM 17 ON PARTS LIST DRAWING PL 190DAG &

PL 190DAGH)

Make sure the unit is completely disconnected from the

air source before attempting to service nozzles.

1. Unscrew spray nozzles (17) from nozzle hub (16)

and inspect for plugging and wear.

2. If a nozzle is plugged or partially plugged, clean out

the orifice and inlet area with a wooden toothpick or

other relatively soft probe. Screwdrivers, wire or

other hard metal items should not be used since

they may scratch and severely damage the orifice.

a. If the nozzles need replacement, obtain new

nozzles.

3. Replace spray nozzles (17) in nozzle hub (16) by

tightly screwing them in.

REMOVAL AND REPLACEMENT OF NOZZLE HUB BUSHINGS (ITEM 15 ON PARTS LIST PL 190DAG &

PL 190DAGH)

1. Unscrew (counter-clockwise - right hand thread)

nozzle hub post (18), and slide nozzle hub bushings

(15) and nozzle hub (16) off the rotary Y-housing

(14) and nozzle hub post (18).

2. Remove any foreign material from nozzle hub gear

teeth.

3. To replace parts, slide one nozzle hub bushing (15)

over the end of the rotary Y-housing (14) up to the

shoulder.

4. Install second nozzle hub bushing (15) onto nozzle

hub post (18) and push nozzle hub onto rotary Y-

housing end.

5. Apply Loctite 243 or 242 to threads of nozzle hub

post (18) and screw (clockwise) into rotary Y-

housing (14) until it seats firmly.

6. Torque to 20 lb-ft (27 Nm).

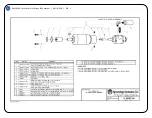

REMOVAL OF #46340 AIR MOTOR DRIVE (SEE PARTS LIST DRAWING PL 46340-190)

1. First make sure the unit is completely disconnected

from the air source.

2. Using a 4 mm Allen wrench, unscrew and remove

both 5 mm socket head cap screws (1) and

respective spring washers (2).

3. You should now be able to lift the air motor drive

REMOVAL/REPLACEMENT OF AIR MOTOR DRIVE COUPLING (ITEM 8 ON PARTS LIST PL 46340-190)

1. If it is necessary to remove the coupling (5) from the

gear motor sub-assembly (11) shaft, tap the

coupling with a rubber or plastic mallet until it

releases from the shaft.

2. To reassemble, align the keyway on the coupling (5)

with the key (6) on the gear motor sub-assembly

(11) shaft and lightly tap the coupling (5) until it

bottoms on the shaft.

Note:

The coupling (5) on the gear motor sub-assembly

(11) shaft has a press fit so the coupling (5) does not

inadvertently come apart during removal or installation

of the gear motor sub-assembly.

REMOVAL OF THE UPPER SHAFT SEAL BODY SUB-ASSEMBLY (4) AND PINION GEAR BUSHING

RETAINER SUB-ASSEMBLY (22) ON PARTS LIST (PL 190DAG & PL 190DAGH) REPAIR KIT (AB-190DAG-

KIT)

1. If it has not already been done, the air motor sub-

assembly should be removed as described in the

Removal of #46340 air motor drive

section above.

2. Next, tap out the groove pin (9), unscrew the upper

shaft seal body sub-assembly (4) and slide off the

shaft (10).

3. Remove gasket (5) from shaft (10).

4. Now unscrew the 5/16” hex head cap screw (19),

remove the lower screw shield (20) and drive plate

(21).

5. Unscrew the pinion gear bushing retainer sub-

assembly (22) and slide off the shaft (10).

6. Pull the rotary Y-housing (14) and bushings (13 &

23) off the stem (12).