10

www.teejet.com

INST

ALLA

TION

APPLIC

A

TION SE

TUP

APPENDIX

INTRODUC

TION

OPER

A

TION

845 Sprayer Control System

SY

STEM SE

TUP

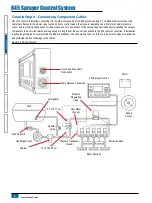

3. Start driving toward the start point of the 300 foot / 100 meter

course.

4.

As the starting point is crossed, press the PLUS

button

once to begin the calibration process. The 845 will count the

Pulses generated while the course is driven.

5.

As the ending point is crossed, press the PLUS

button

once. The number displayed on the screen is the speed

calibration number.

6.

To accept the value, press the PROGRAM

button. To edit

the value, use the PLUS button or MINUS

buttons.

The number of Pulses is automatically stored as the new

calibration.

*To confirm Automatic Speed Calibration distance, first complete

the calibration procedure. Advance to the Distance Counter step.

Drive the vehicle across the same 300 foot / 100 Meters course,

turning the Master Switch “ON” at the starting point and “OFF”

at the finish point. The distance measured should be 300 feet /

100 Meters (+/- 6 feet/+/- 1.8 Meters).

Figure 3-5: Speed Sensor Automatic Calibration

NOTE: When the Automatic Calibration Mode is activated, no other

functions are possible until the console receives Pulses for

calibration. To deactivate the Automatic Calibration Mode,

press the PLUS

button until a number is displayed.

Distance Counter

The Distance Counter step is not a calibration step. It is a help

function that can be used to measure a distance such as to confirm

Automatic Speed Calibration. No value can be entered here. This

feature measures distance in feet/Meters.

When using this function all section switches must be set to off to

avoid spraying.

1. Turn Master Switch on to start distance counter.

2. Drive the desired distance.

3.

Turn Master Switch off to stop distance counter.

To clear an existing distance value, press and hold the PLUS

and MINUS buttons simultaneously for 3 seconds.

Figure 3-6: Distance Counter

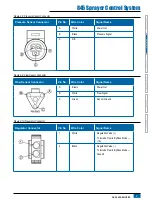

Pressure Sensor Installed

Select if a pressure sensor is installed.

If a flow sensor is not installed, this step is automatically set to

“Yes” and cannot be changed.

Figure 3-7: Pressure Sensor Installed

Zero Pressure Reference

This step is only available if “Pressure Sensor Installed” is set to

“Yes”.

The Zero Pressure Reference is used to calibrate the zero pressure

setting of the pressure sensor installed on the system. The

pressure sensor used with the console is a current type sensor and

uses a 4-20 mA reading. “4.0 mA” represents “zero” pressure.

1.

If necessary, run the Automatic Calibration to determine the

Zero Pressure Reference setting.

2. Enter the value for the Zero Pressure Reference setting.

Figure 3-8: Pressure Sensor, Zero Pressure