INST

ALLA

TION

APPLIC

A

TION SE

TUP

APPENDIX

INTRODUC

TION

OPER

A

TION

11

845 Sprayer Control System

98-05349-ENUS R0

SY

STEM SE

TUP

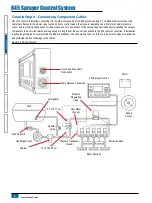

Automatic Calibration

Make sure that the sprayer pump is turned off and that there is

absolutely no pressure in the system (release pressure held by

boom control valves and Tip/Nozzle body check valves).

In some cases, it may be best to remove the sensor from the

plumbing system to complete the calibration.

1.

Press and hold the PLUS and MINUS

buttons

simultaneously for 3 seconds to start auto calibration mode.

The lower left portion of the display will count from 1 through 10

during the calibration.

Once the display finishes counting, it should display a number

close to 4.0 (+/- 0.2).

2. To accept the value, press the PROGRAM

button. To edit

the value, use the PLUS button or MINUS

buttons.

Figure 3-9: Zero Pressure Reference Automatic Calibration

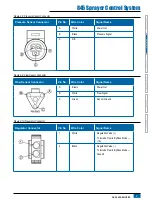

Maximum Pressure Rating

This step is only available if “Pressure Sensor Installed” is set to

“Yes”.

The Maximum Pressure Rating is used to establish the maximum

rating of the pressure Sensor in the system. This number can be

found stamped on the pressure sensor itself.

NOTES: Do not change the value to “0” even if there is no pressure

sensor installed. The Maximum Pressure cannot be set

lower than the Minimum Pressure. The Minimum Pressure

defaults to 10 psi / 0.6 bar, below this value regulation is

stopped.

Figure 3-10: Maximum Pressure Rating

Minimum Pressure

Below the Minimum Pressure value, regulation is stopped, except

when using lane spraying (GLM or LKM).

Figure 3-11: Minimum Pressure

Flow Meter Installed

Select if a flow meter is installed.

If a pressure sensor is not installed this step is automatically set to

“Yes” and cannot be changed.

If lane spraying is selected under Units (GLM or LKM), this setting

will always be set to “Yes” and cannot be changed.

Figure 3-12: Flow Meter Installed

Flow Meter Calibration

This step is only available if “Flow Meter Installed” is set to “Yes”.

Flow Meter Calibration determines the flow meter Pulses based on

a known volume of fluid.

1.

If necessary, run the Automatic Calibration to determine the

number of pulses.

NOTE: The automatic calibration procedure is recommended for

maximum accuracy.

Or note the flow meter calibration number found on the factory

calibrated tag.

2.

Enter the number of pulses.

Pressing the AUTO/MAN

button will switch between normal

value and decimal value (/10). Decimal values can be used with

very low flow calibration values to improve regulation accuracy.