4

6.

DO NOT

use damaged, perforated, or weakened fluid hose.

7.

DO NOT

use a GunJet® with a faulty or damaged Trigger Lock.

8.

DO NOT

operate a spray gun if there are any leaks from the packings,

fittings, hoses, etc. Fluids that are under high pressure can penetrate

skin, cloth, etc., and cause serious injury.

9.

DO NOT

touch any metal parts of the gun or accessories when spraying

hot liquids or severe injury can occur.

10.

DO NOT

handle a spray gun without

a tip or nozzle any differently than

one with

a tip or nozzle. Even with the tip or nozzle removed, the spray

gun can discharge a large volume of liquid at a high velocity.

SAFETY SHOULD ALWAYS BE OBSERVED:

1.

DO

use a two-handed control of PW4000A GunJet at all times. Grasp

spray gun firmly with both hands. If an extension is used, grasp the

extension. (Insulated extension if spraying hot liquids.)

2.

DO

adopt a secure body stance prior to and during spray operation to

safely control the high reactionary force of this unit.

3.

DO

impress on other people in the spraying area the importance of

obeying strict safety precautions for everyone’s safety.

4.

DO

develop a habit of shutting off the power to the pump, relieving

fluid pressure from gun and hose by actuating trigger until all fluid

ceases to flow, and setting the Trigger Lock in the locked position,

before attempting to remove the tip, nozzle, gun or any part of the

gun, or when gun is not in use.

5.

DO

check operation of Trigger Lock before each spray period. Trigger

Lock must hold the Trigger to its forward position. (Adjust if necessary;

s

ee section Trigger Adjustment Procedure.)

6.

DO

carefully check and tighten threaded connections regularly. Make

them secure and leak proof.

7.

DO

flush gun after each spray period using the same safety precautions

as used during spraying operations. Always use the lowest possible

pressure for flushing.

8.

DO

keep gun clean and dry to allow for positive grip.

Summary of Contents for GunJet PW4000A

Page 1: ...PW4000A GunJet Spray Gun USER GUIDE spray com MI PW4000A...

Page 8: ...8 Figure 1 Figure 2...

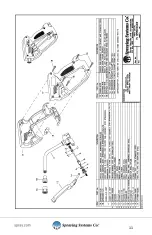

Page 9: ...9 PARTS LIST...

Page 10: ...10...

Page 11: ...11...