5

9.

DO

use GunJet® in a well-ventilated area and make sure spray gun is

grounded properly when used in a possibly explosive or inflammable

environment. A grounded-type hose should be used.

IMPORTANT: In case of the slightest appearance of skin penetration from

spray, CONSULT A PHYSICIAN IMMEDIATELY!

INSTALLATION

1.

Before installing GunJet

®

to hose, select WashJet

®

tip or, if desired, an

appropriate extension and WashJet nozzle for your application. Install

on gun with nozzle positioned for your particular spraying needs and

tighten.

2.

Make sure all power is turned off to the pump. Attach GunJet to

high-pressure hose with rating to meet or exceed the maximum

operating pressure to be used. When spray gun is being used in a

possible explosive or flammable environment, a grounded-type hose

should be used.

3.

Follow your pump and component parts manufacturer’s

recommendations for operation, but in any case, do not exceed

the pressure or temperature of the lowest rated component within the

system.

4.

Make sure all power to the pump is turned off and there is no pressure

in any part of the system. Examine all connections, making sure they

are of the proper type and are secure.

5.

Before turning on the pump and holding the GunJet in downward

vertical position pointed away from body, familiarize yourself with the

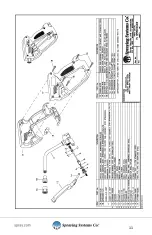

operation of the Trigger Lock (17)

6.

Make sure Trigger Lock (17) is in “locked” position. Do not turn on the

pump power or operate spray gun if Trigger Lock is not operating

properly.

Summary of Contents for GunJet PW4000A

Page 1: ...PW4000A GunJet Spray Gun USER GUIDE spray com MI PW4000A...

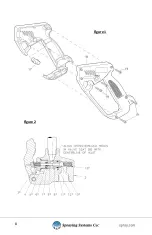

Page 8: ...8 Figure 1 Figure 2...

Page 9: ...9 PARTS LIST...

Page 10: ...10...

Page 11: ...11...