3

•

Spraying Systems Co. waives all liability and responsibility in the event of

usage not in compliance with our recommendations and/or any

unauthorized interventions to our equipment.

•

Special Conditions of Use:

1.

Flameproof joints are not intended to be repaired, contact

manufacturer.

2.

Exposed metal of spray nozzle shall be electrically bonded to a

suitable earthing facility to reduce buildup of electrostatic charging.

INTRODUCTION

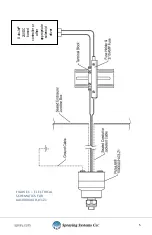

The AA(B)10000AUH-03-Z1 PulsaJet

®

nozzle is a high speed, electrically actuated

hydraulic spray nozzle that can be used in Zone 1 rated hazardous areas when

properly installed, operated and maintained. Wetted parts are constructed of

stainless steel, PPS, PEEK, and perfluoroelastomers (FFKM) for superior

temperature and chemical resistance.

SPECIFICATIONS:

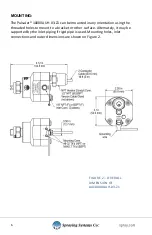

•

Power Requirements: 27VDC Max., 0.30 AMPS Max.

•

Inlet connections: 1/8 NPT for AA10000AUH-03-Z11/8 BSPT for

AAB10000AUH-03-Z1

•

Electrical conduit connection: 1/2 NPT for AA10000AUH-03-Z1 M12X1.5 for

AAB10000AUH-03-Z1

•

Maximum Operating Pressure: 100 psi (7 bar)

•

Maximum Flow rate: 0.47 gpm @ 100 psi (1.8 lpm @ 7 bar)

•

Maximum Ambient Temperature: 104°F (40°C)

•

Weight: Approximately 25 oz. (0.7 kg)

NOTES

:

•

The solenoid portion of the AA(B)10000AUH-03-Z1 PulsaJet nozzle is

assembled, tested, and sealed at the factory for safe and proper operation.

This portion of the unit should not be disassembled for cleaning or service.

•

Solenoid coil is factory sealed, conduit seal not required

•

Access to the valve portion of the AA(B)10000AUH-03-Z1 PulsaJet nozzle for

cleaning and/or servicing can be gained by removing the spray tip and

unscrewing the seat.

•

Fuse must be connected for use in a hazardous environment.