4

| / /

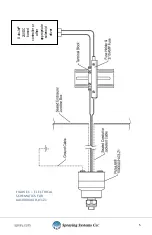

INSTALLATION

FLUID CONNECTIONS:

Fluid connections should be made using the appropriate 1/8” pipe connection. If a

metal fitting is used, appropriate thread sealer should be applied to the threads

prior to assembly. For those applications requiring recirculation,

two 1/8” pipe connection ports are provided. If recirculation is not required, one

of the ports should be plugged using 1/8” pipe plug which is provided with each

unit.

ELECTRICAL CONNECTIONS:

Electrical conduit connection for conduit fitting accepts 1/2” NPT (M) for NPT

version. The conduit must protect the electrical cable from mechanical damage

and terminate in a sealed enclosure or junction box appropriate for the hazardous

location. For BSPT version, an Ex d rated cable gland is used with cable. The fuse

holder and a 3/10-amp fuse should be used as shown in Figure 1. The ground

connection of the PulsaJet® 10000AUH-03-Z1 must be attached to a true ground.