5

spray.com | 1.800.95.SPRAY | Intl. Tel: 1.630.665.5000

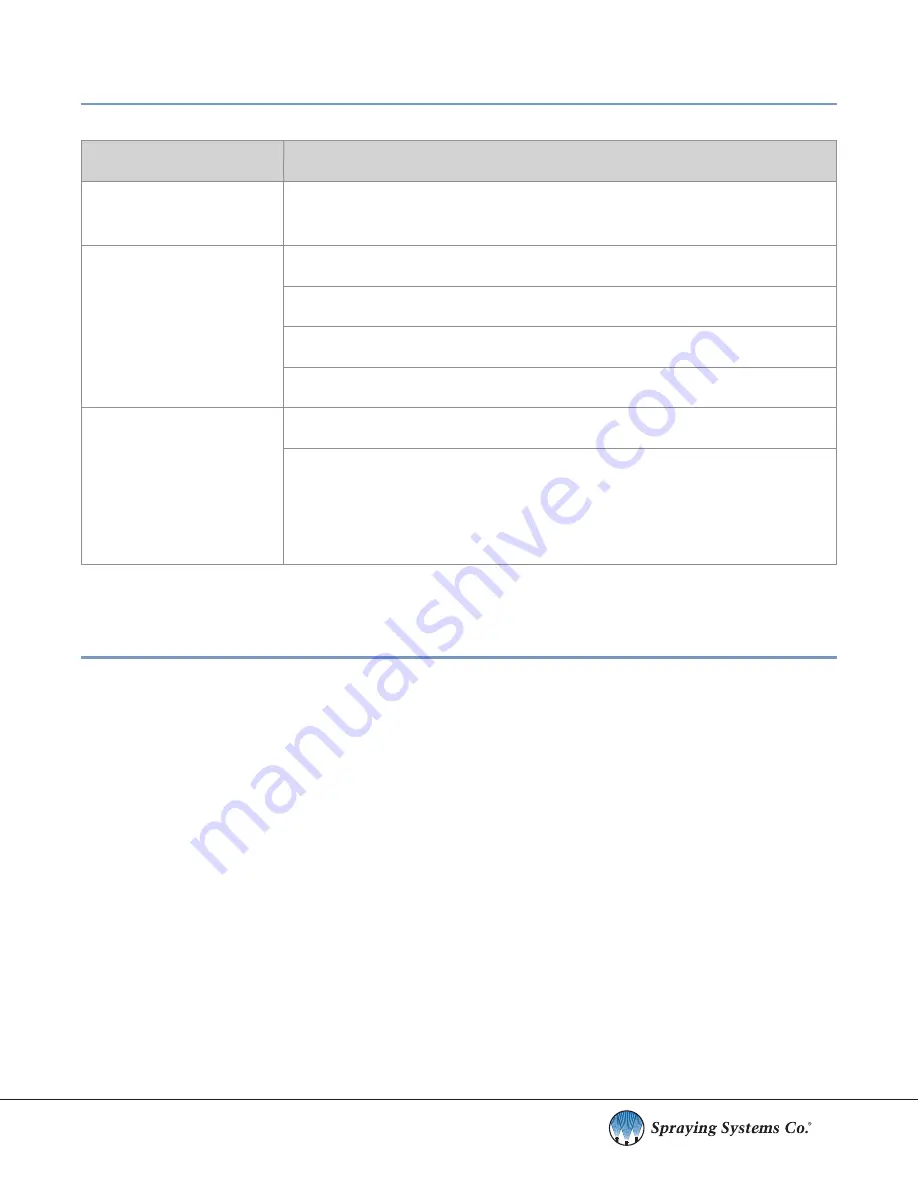

TROUBLE SHOOTING GUIDE

The following table indicates various potential modes of failure for this product.

Mode of Failure

Preventative or Corrective Actions

Poor spray performance

Check unit for external damage. Look for evidence of mishandling that may have damaged

shafts, bearings, or alignment.

Nozzle hub fails to rotate and

no liquid passes:

Check for liquid pressure and volume at the unit.

Check strainer for filter blockage.

Remove nozzles and check for obstructions.

While nozzles are off, recheck for flow through the body.

If the unit fails to rotate and

sufficient liquid passes:

Check for freedom of rotation, by hand, in the vertical and rotational axis.

If the unit is free and still does not rotate, check for:

1. Contamination in the unit.

2. Wear of any of the bushings or bearings.

3. Galling and straightness of the shaft.

WARNING:

Replace all defective or worn parts.

SPRAYING SYSTEMS CO. WARRANTY

Seller warrants that its products will conform to and

perform in accordance with the products’ specifications.

Seller warrants that the products do not infringe upon

any copyright, patent or trademark. THE FOREGOING

WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED

TO, THOSE CONCERNING MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

Because of the difficulty of ascertaining and measuring

damages hereunder, it is agreed that, except for claims for

bodily injury, Seller’s liability to the Buyer or any third party,

for any losses or damages, whether direct or otherwise,

arising out of the purchase of product from Seller by Buyer

shall not exceed the total amount billed and billable to the

Buyer for the product hereunder. IN NO EVENT WILL SELLER

BE LIABLE FOR ANY LOSS OF PROFITS OR OTHER SPECIAL

OR CONSEQUENTIAL DAMAGES, EVEN IF SELLER HAS

BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

For newly purchased units, the warranty is 18 months

from the date of shipment or 12 months from the date of

installation, whichever occurs first. This warranty

includes manufacturing defects but does not cover wear

of components. This warranty will be void if parts other

than those supplied by Spraying Systems Co. are used

or if the unit is modified by anyone other authorized

Spraying Systems Co. personnel. Modifications to the unit

may void the 3-A symbol and put the unit outside

3-A sanitary compliance.

.