13

The following check ups should be carried out at regular 12 months intervals:

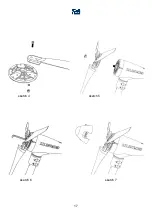

11.1 Rotor blades

Check if the blades show damages like broken edges, damaged surface or cracks. If

you notice any damage, the generator must not be used any longer. Check the

screwing one day after mounting and after that every 3 months. Eventually that you

can turn to a longer interval.

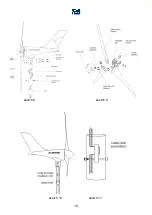

11.2 Srews

Check that all accessible screws are correctly fixed. Especially the hexagon srews of

the connection to the hub, the central shaft nut and the fixing of the mast must be

checked (see page 10, 11 and page 17, sketch 4, 5 ,6 ,7 and page 18, sketch 8, 9).

11.3 Bearings and gaskets

The bearing of the generator shaft and the bearing of the yaw shaft are permanently

lubricated. Please check these bearings as to free movement, bearing play and

watertightness. Deficient bearings must be replaced.

11.4 Corrosion protection

The complete housing is made of seaworthy alumine and additionally powder coated.

If the outer layer is damaged, there is a risk of corrosion. Please paint these spots

with suitable varnish (RAL9010)

11.5 Mounting construction

Check this construction in line with the instructions concerned (optional).

11.6 Electrical system

Please first stop the Silentwind generator so that all wires carry no voltage. Check if

all connections are properly fixed and not corroded. Possible corrosions must be

removed and treated with contact spray. Give special attention to the battery

connections: they must be clean and greased with vaseline. Check the battery in line

with the instructions of the producer and (if necessary) refill with destilled water. In

case more than 1 battery is used check that all batteries have the same capacity and

state of charge.