24

Maintenance

sion is the lowest tension at which the belt will not slip under peak load

conditions. Check tension frequently during the first 24-48 hours of run-in

operation. Overtensioning shortens belt and bearing life. Keep belts free

from foreign material which may cause slipping. Never apply belt dress-

ing as this will damage the belt and cause early failure. A Dodge

®

V-Belt

Tension Tester is an alternate method for tensioning V-belts. Check with

you local belt supplier.

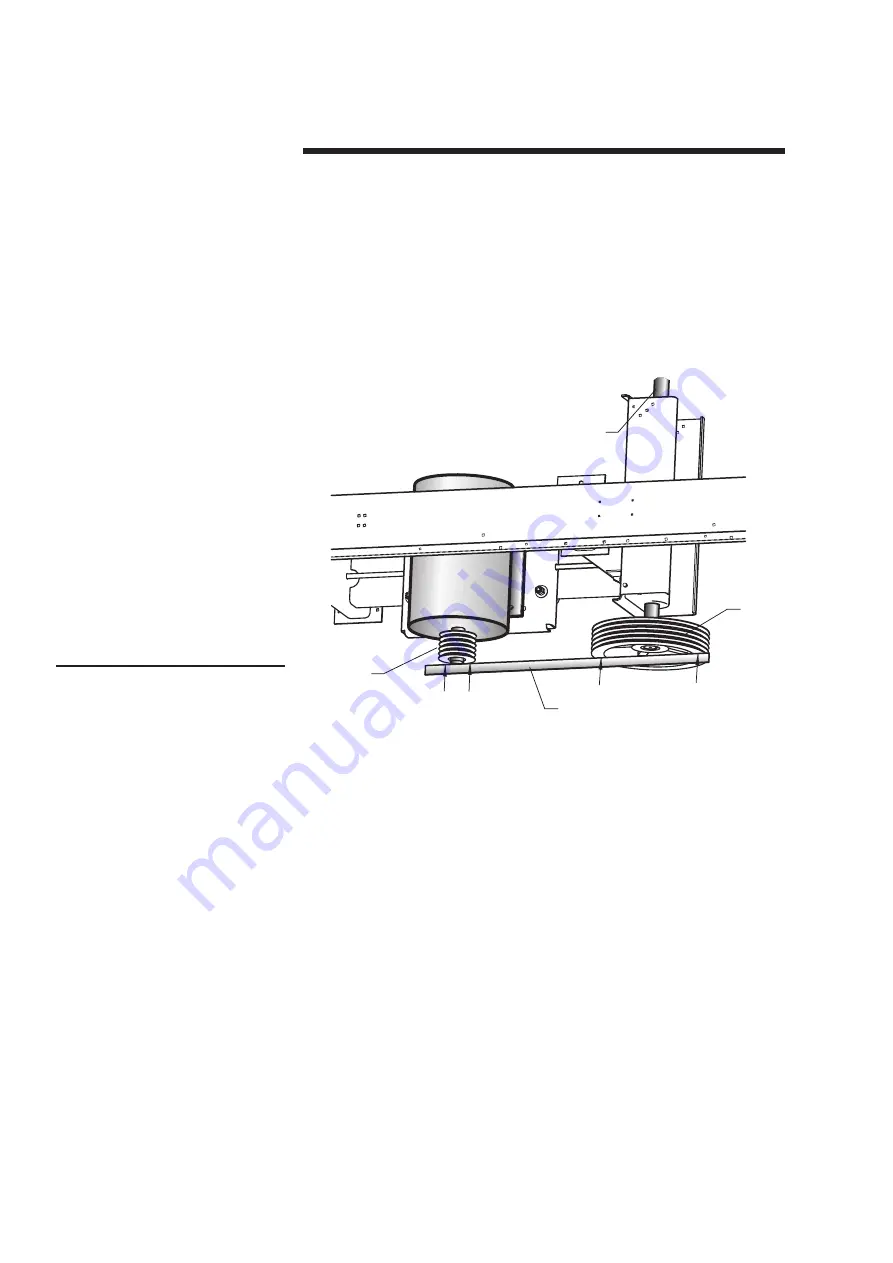

Sheave alignment

• The motor sheave is to be positioned as close as possible to the motor

in order to minimize stress on the motor bushings.

• The motor and fan sheaves may have grooves that are not used. The

bottom surface of the motor and fan sheaves must be aligned within

3mm of each other and level within

1

⁄

2

° (3mm in 305mm) in order to

not adversely affect belt and sheave life.

• Alignment can be achieved by placing a straight edge across the

sheaves making sure that it is level and measuring down to the bot-

tom surface of both sheaves at four points.

• The belt is to be located in the grooves closest to the motor center

-

line.

Figure 3

SHEAVE

FAN SHAFT

SHEAVE

STRAIGHT EDGE