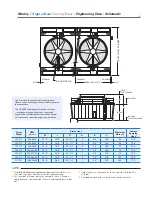

Specifications

Specification Value

Marley

/

Sigma Steel

Cooling Tower

/

Specifications: Base

16

5.3

Motor shall be located outside the fan

cylinder at the fan deck, and shall be

connected to the speed reducer by

a tubular stainless steel, dynamically

balanced driveshaft equipped with neo-

prene flexible coupling elements.

5.4

A galvanized oil gauge and drain line

shall extend from the gear reducer to

the vicinity of the motor, and shall be

equipped with a dip stick for oil level

measurement.

5.5

The complete mechanical equipment

assembly for each cell shall be sup-

ported by a rigid, unitized support that

resists misalignment between the

motor and the gear reducer. Support

shall be heavy-wall tubular steel, to

which heavy plate platforms for the

motor and gear reducer have been

welded and the assembly shall be hot-

dip galvanized after fabrication. The

support assembly shall also provide

an inlet connection for incoming hot

water, and shall serve as a crossover

pipe to deliver water to both sides of

the tower.

5.6

The mechanical equipment assembly

shall be warranted for no less than five

(5) years. This warranty shall cover the

fan(s), speed reducers, driveshafts and

couplings, and the unitized supports.

■

The driveshaft turns at the motor speed and is, therefore, most sensi-

tive to operational imbalance. Stainless steel manufacture assures that

the driveshaft will not become unbalanced as a result of corrosion.

■

Fans of the size used on large cooling towers are applied at speeds and

horsepower that generate considerable torque—and structural tubular

steel resists this torque very effectively. Marley torque-tube assures that

all of the mechanical equipment remains aligned, and that the rotating

fan is properly positioned within the fan cylinder.

■

The value of a 5 year mechanical equipment warranty speaks for itself.

Except for the motor, all of the mechanical equipment on a Marley

tower is made by SPX Cooling Technologies. Cooling tower vendors

who purchase commercial fans, gear boxes, driveshafts, etc. may

require that you deal directly with those commercial suppliers for war-

ranty satisfaction.

Summary of Contents for Marley Sigma Marley Sigma Steel

Page 1: ...Marley Sigma Steel CoolingTower Engineering Data Specifications...

Page 2: ......

Page 4: ......