30

Sheave Alignment

Always shut off electrical power to the fluid cooler fan motor prior

to performing any inspections that may involve physical contact

with the mechanical or electrical equipment in or on the fluid cooler.

Lock out and tag out any electrical switches to prevent others from

turning the power back on. Service personnel must wear proper

personal protective clothing and equipment.

• The motor sheave is to be positioned as close as possible to the motor

in order to minimize torque on the motor bushings.

• The motor and fan sheaves may have grooves that are not used. The bot-

tom surface of the motor and fan sheaves must be aligned within 3mm of

each other and level within

1

⁄

2

° (3mm in 30cm) in order to not adversely

affect belt and sheave life.

• Alignment can be achieved by placing a straight edge across the top of

the sheaves making sure that it is level and measuring down to the bot-

tom surface of both sheaves at four points.

• The number of grooves on the motor and fan sheaves may not match

each other, or the number of grooves on the belt. Always install the belts

on the highest grooves on the fan sheave. Doing so will reduce the force

on the fan shaft bearings, thus increasing their life.

maintenance

Warning

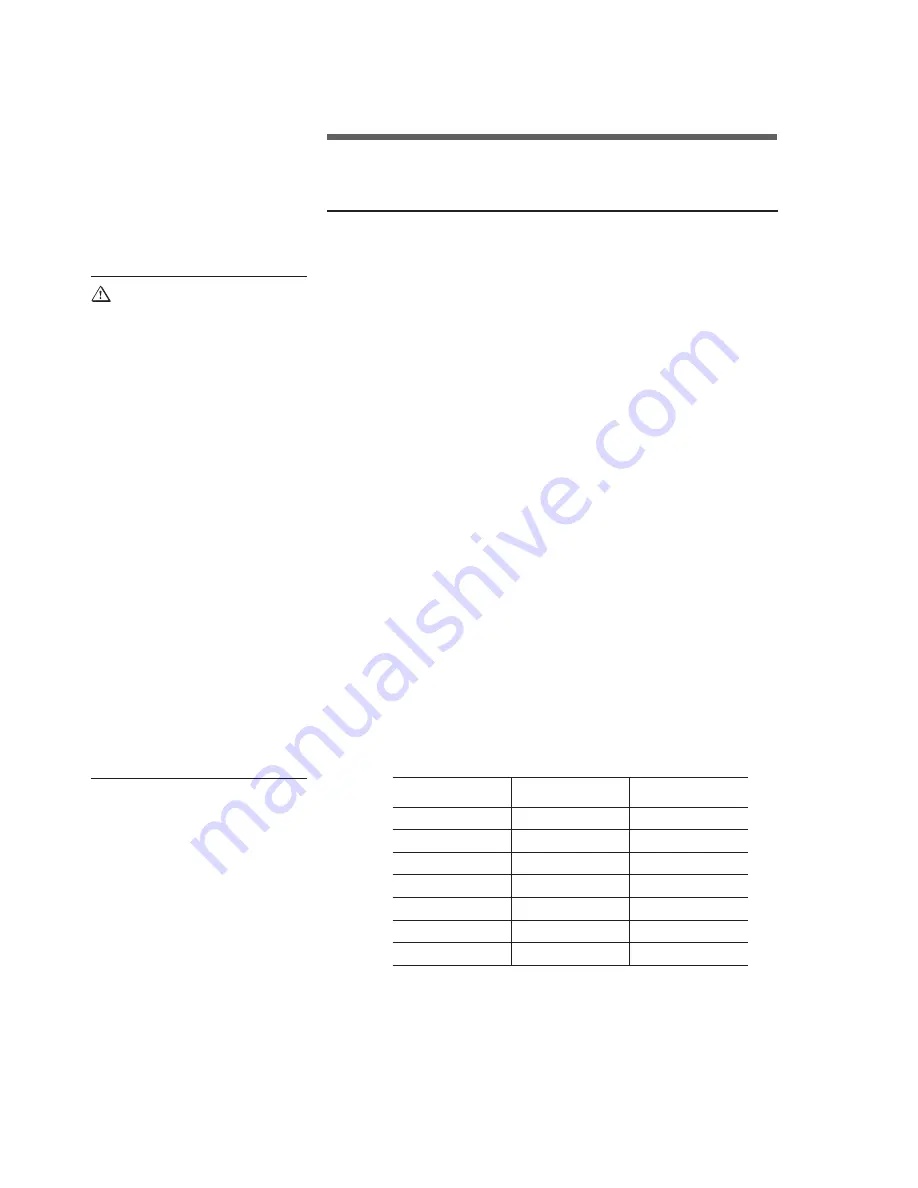

Bushing

Fastener

Torque

N·m

SH

1

⁄

4

- 20

8

SDS

1

⁄

4

- 20

8

SD

1

⁄

4

- 20

8

SK

5

⁄

16

- 18

18

SF

3

⁄

8

- 16

30

E

1

⁄

2

- 13

47

F

9

⁄

16

- 12

88

Bushing Fastener

Torque Values