41

maintenance schedule

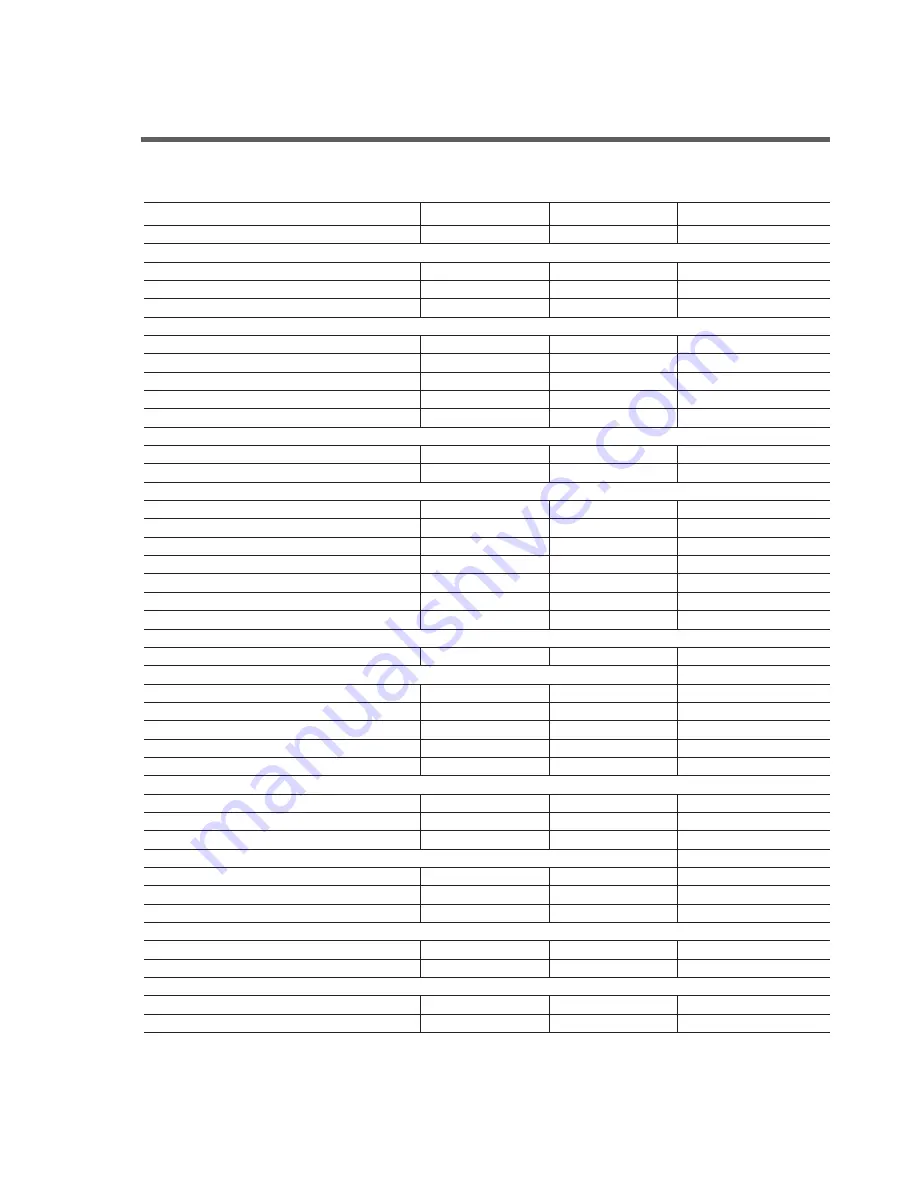

Maintenance Service

Monthly

Semi-annually

Seasonal Startup or Annually

Inspect General Condition and Operation

x

x

Observe Operation of:

Mechanical–motor, fan and drive mechanism

x

x

Makeup valve (if equipped)

x

x

Inspect for unusual noise or vibration

x

x

Inspect and Clean:

Air inlet

x

x

PVC drift eliminators

x

x

Distribution basin, nozzles and collection basin

x

x

Fan and pump motor exterior

x

x

Coil surface

x

Check:

Collection water basin level

x

x

Blowdown–adjust as required

x

x

Geareducer Drive (if equipped):

Check for loose fasteners including oil drain plug

x

Check oil level, check for / repair oil leaks

x

x

Change oil

R

Make sure vent is open

x

x

Check driveshaft or coupling alignment

x

Check for loose driveshaft or coupling fasteners

x

Check driveshaft or coupling bushings or flex element for unusual wear

x

x

Lube lines (if equipped):

Check for oil leaks in hoses or fittings

x

R

x

Belt drive (if equipped):

Fan shaft bearing lubrication (every 3 mo.)

every 3 months

every 3 months

Check and tighten support fasteners

x

Check shaft, sheave and belt alignment

x

Check belt tension and condition

x

x

Check sheave bushing fastener torque

x

Fan:

Check and tighten blade and hub fasteners

x

Check fan blade pitch and tip clearance

x

Check fan cylinder for loose fasteners

x

Motor:

Lubricate (grease as required)

R

Check mounting bolts for tightness

x

Operate at least

3 hours a month

3 hours a month

3 hours a month

Basin Heater (if equipped):

Check for proper operation of temp/low water level sensor

x

Inspect/clean buildup of contaminant from sensor

x

x

Structure:

Inspect/tighten all fasteners

x

x

Inspect and touch up all metal surfaces

x

R

— Refer to Component User Manual

Note:

It is recommended at least weekly, that the general operation and condition be observed. Pay attention to

any changes in sound or vibration that may signify a need for closer inspection.