Sheet No.

Issue Date: Rev. D, July 25, 2005

© SPX Corporation

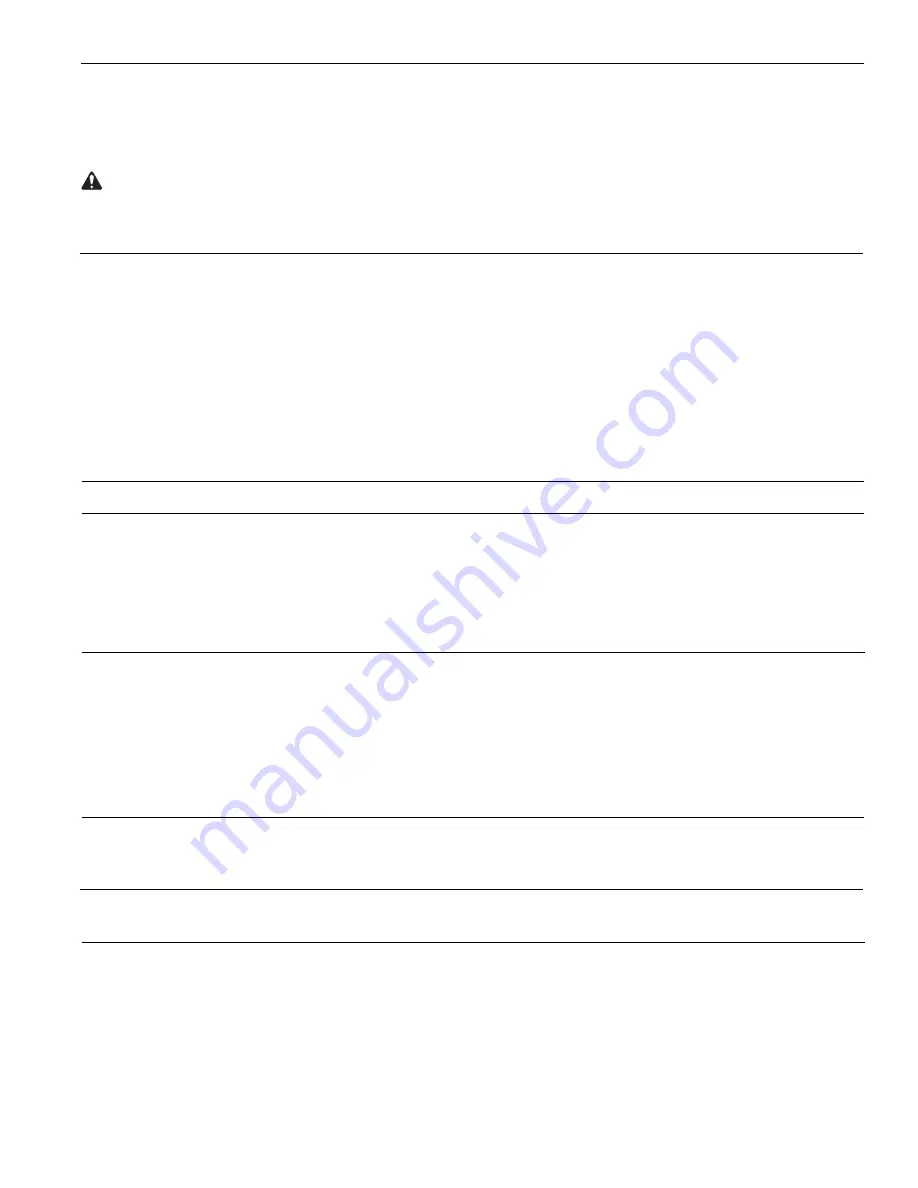

Jack does not lift

Jack lifts only partially

Jack advances slowly

Jack lifts load, but doesn’t hold

Jack leaks oil

Jack will not retract

Jack retracts slowly

1. Control valve in wrong position.

2. Low/no oil in reservoir.

3. Air-locked system.

4. Load is above capacity of jack.

5. Delivery valve and/or bypass

valve not working correctly.

6. Seals worn out or defective.

1. Move control valve to UP position.

2. Fill with oil and bleed system.

3. Bleed system.

4. Use correct equipment.

5. Clean to remove dirt or foreign

matter. Replace oil.

6. Replace with seal kit No. 515349 for

the 5093 or seal kit No. 515353 for

the 5094.

1. Too much or not enough oil.

1. Check oil level.

1. Pump not working correctly.

2. Leaking seals.

1. Replace with seal kit No. 515349 for

the 5093 or seal kit No. 515353 for

the 5094.

2. Replace with seal kit No. 515349 for

the 5093 or seal kit No. 515353 for

the 5094.

1. Cylinder packing is leaking.

2. Valve not working correctly

(suction, delivery, release, or

bypass).

3. Air-locked system.

1. Replace with seal kit No. 515349 for

the 5093 or seal kit No. 515353 for

the 5094.

2. Inspect valves. Clean and repair

seat surfaces.

3. Bleed system.

1. Worn or damaged seals.

1. Replace with seal kit No. 515349 for

the 5093 or seal kit No. 515353 for

the 5094.

1. Control valve in wrong position.

1. Move control valve to DOWN

position.

1. Cylinder damaged internally.

1. Send jack to OTC-authorized service

center. (Refer to OTC Form No.

104031.)

Troubleshooting Guide

Repair procedures must be performed in a dirt-free environment by qualified personnel who are familiar with

this equipment.

CAUTION: To prevent personal injury, all inspection, maintenance, and repair procedures must be

performed when the jack is free of a load (not in use) and disconnected from the air supply.

Trouble

Cause

Solution

Parts List & Operating Instructions

Form No. 107273

3 of 3