Parts List & Operating Instructions

Form No. 555231, Sheet 1 of 3, Back

Safety Precautions

Warning: Spring compression creates a potentially dangerous situation because of the energy

stored between the spring mounts. Failure to correctly position the strut assembly in the tool could

result in serious injury from a sudden release of strut assembly parts. To prevent personal injury,

•

Study, understand, and follow the safety precautions and operating instructions included with the

strut spring compressor. If the operator cannot read these instructions, operating instructions and

safety precautions must be read and discussed in the operator's native language.

•

Wear eye protection that meets ANSI Z87.1 and OSHA standards.

•

Use this equipment for automotive strut springs only.

•

Check the condition of the strut spring compressor before each use;

do not use the equipment if it is damaged, worn, or modified.

•

Align the strut assembly before compressing. The spring should

be parallel to the forcing screw and on the centerline of the foot

support.

•

Release and reposition the strut assembly if it is difficult to compress

the spring, or if the spring bows.

•

Compress the spring only until it is loose in its spring mounts.

Stop compressing if the spring or the arms bottom out.

•

Do not remove the piston rod nut until the spring is compressed

enough to be loose in the mount.

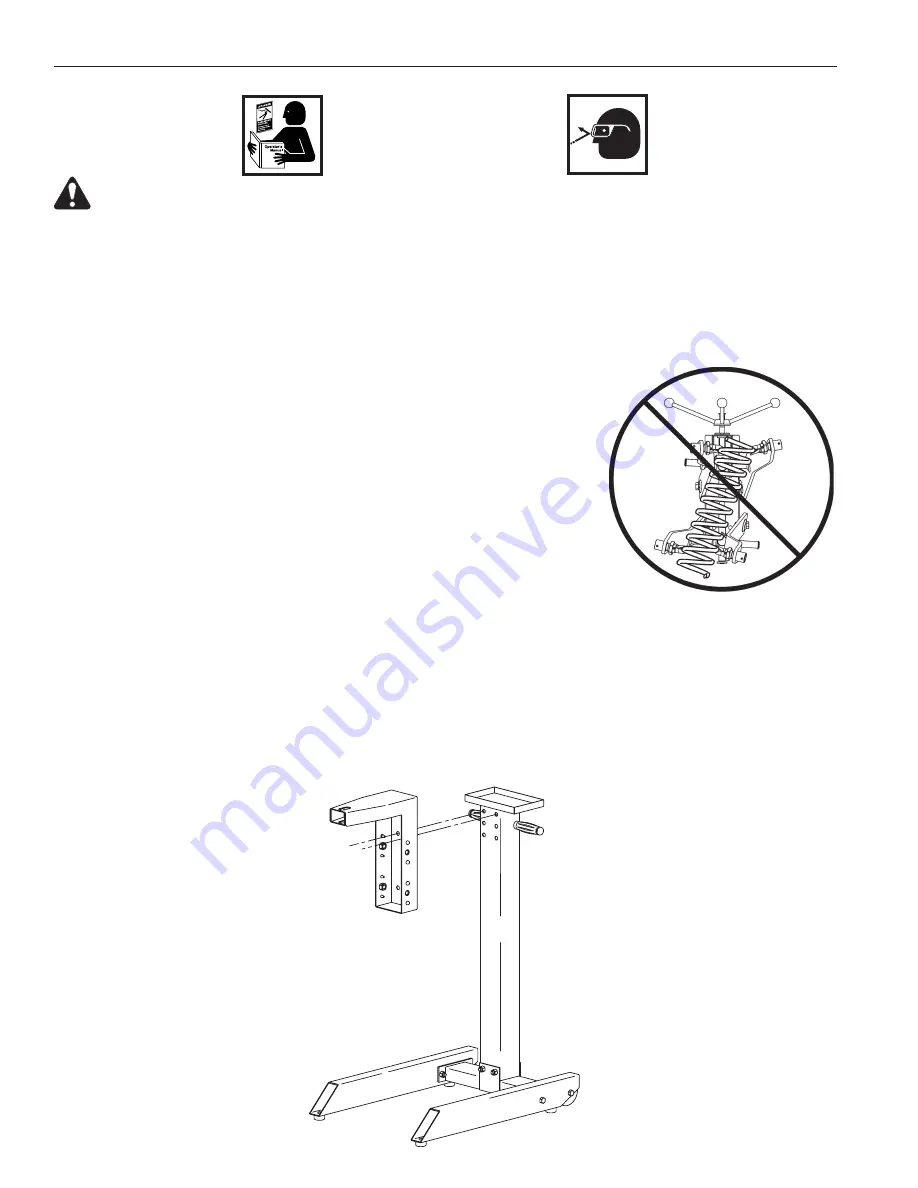

Use the top two holes

in the strut spring

compressor body to

mount the compressor

on the No. 6582 optional

stand as shown.

(Hardware is included

with the stand.)

Use all four holes on the

back of the strut spring

compressor body to

mount the compressor to

a wall.

Assembly

The strut spring compressor may be mounted on a wall, or on an optional mobile stand (part no. 6582).