Parts List & Operating Instructions

Form No. 555231

Operating Instructions

Removal

1. Refer to the vehicle service manual, and follow the manufacturer's recommended procedure to remove the

strut assembly from the vehicle.

2. Mark the position of the spring in relation to the lower platform and top mount; this notes the correct position

for installation.

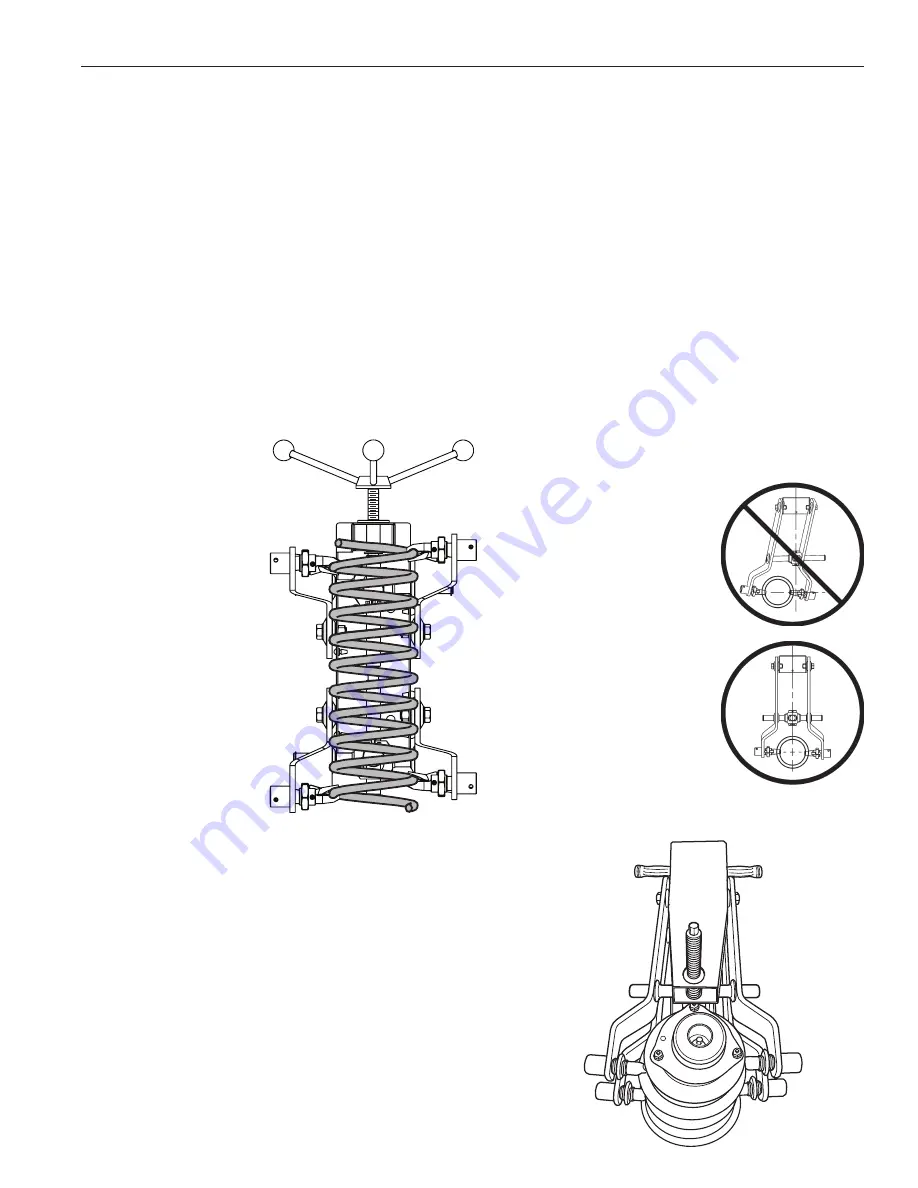

3. Choose the lowest possible spring coil to insert into the lower left jaw; hand tighten the locknut. See Fig. 1.

4. Load the opposite side of the same coil in the lower right jaw; hand tighten the locknut.

Note: It may be

necessary to move the compressor arms to access the coil.

5. Choose the highest possible spring coil to insert into the upper left jaw; hand tighten the locknut.

6. Load the opposite side of the same coil in the upper right jaw; hand tighten the locknut.

Note: The bridge accessory is designed to be used with the strut spring compressor on strut springs that

cannot be compressed enough to remove the retaining nut. Refer to the instructions on the next page.

7. Before servicing the strut assembly,

align the strut spring with the forcing screw

on the strut spring

compressor as shown in Figure 1.

8. Equally space the top arms on the top trunnion as shown in

Fig. 2. The forcing screw must be centered between the two

top arms.

9. Operate the actuating screw to compress the spring only until

the strut cartridge is loose in the spring mounts.

IMPORTANT:

It is not necessary to over-compress the spring. The

spring should be compressed only until the strut tube

is loose in the spring.

10. Remove the piston rod nut, and service the strut as required.

Center the

forcing screw

between the

two top arms.

Figure 2

Fasten

locking jaw to

low side of coil.

Fasten locking

jaw to high side

of same coil.

Fasten locking

jaw to high side

of same coil.

1

3

4

2

Figure 1

Fasten

locking jaw to

low side of coil.

Sheet No. 2 of 3

© 2009 SPX (Rev. A, October 29, 2009)