3

2.0 Description

2.1 Function

Dual tower regenerative desiccant dryers are utilized to dry

compressed air to dew points below the freezing point of

water or reduce the moisture content to low levels for use in

critical process applications.

Air is dried by using two identical towers, each containing a

desiccant bed. While one tower is on-stream drying the com-

pressed air, the other tower is off-stream being regenerated

(reactivated, i.e., dried out).

Desiccant dryers lower the dew point by adsorbing most of

the water vapor present onto the surface of the desiccant.

Adsorption occurs until an equilibrium is reached between

the partial pressure of the water vapor in the air and that on

the surface of the desiccant.

Desiccant can then be regenerated by desorbing the water

collected on its surface. Regeneration occurs by expanding

a portion of the dried air to atmospheric pressure. This very

dry air (called purge air) causes the moisture to desorb from

the desiccant and then carries the desorbed water out of the

dryer.

2.2 Operation

Compressed air enters the dryer and is directed to TOWER 1

through valve (A) and then exits the dryer through shuttle

valve (B). A portion of the dried air is throttled to near atmo-

spheric pressure by means of an orifice (C). This extremely

dry, low pressure air flows through and regenerates the

desiccant in TOWER 2 and is then exhausted through purge/

repressurization valve (D) and exhaust muffler (E) to atmo-

sphere.

After a set time, the automatic solid state timer closes

purge/repressurization valve (D) allowing TOWER 2 to repres-

surize slowly.

At the end of 2 minutes, valve (F) opens and Tower 1 depres-

surizes. The main air flow is now dried by TOWER 2 while

TOWER 1 is regenerated.

TOWER

1

TOWER

2

E

D

F

C

B

A

TOWER

1

TOWER

2

A

F

D

E

B

C

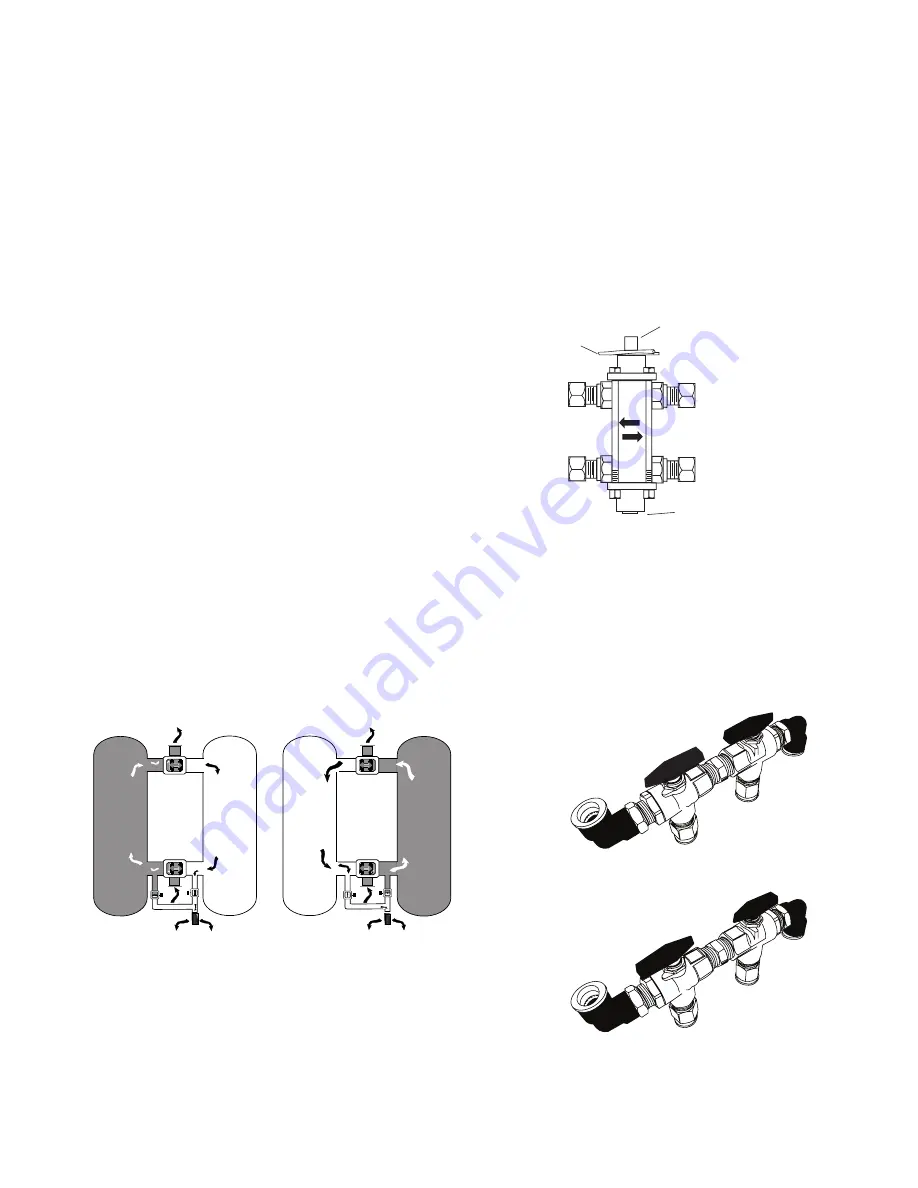

Figure 1 – Flow Schematic

Models 7 through 50

2.3 Air By-Pass Assembly

An optional air by-pass assembly is available for all models.

When ordered with the dryer, the by-pass assembly is factory

installed inside the dryer cabinet. Make sure the by-pass

assembly is in the desired mode: "Dry" (compressed air flow

through the dryer) or "By-pass" (compressed air by-passes

the dryer).

2.3.1 Models 7 and 13

The by-pass assembly includes a by-pass valve with a manu-

ally operated spool. One end of the spool is marked "Push

to Dry" and the other end is marked "Push to Bypass". To

select the desired mode, remove the locking pin, push and

fully depress the appropriately marked end of the spool, and

install the locking pin in the opposite end.

IN

OUT

Push to by-pass dryer

Locking Pin

Push to Dry

Models 7 and 13

Optional by-pass

Figure 2a – Air Bypass Assembly

Models 7 and 13

2.3.2 Models 20, 25, 30, 35, and 50

The by-pass assembly includes two manually operated three-

way valves. To select "Dry" mode, rotate the valve handles

so that the arrows point away from each other. To select

"By-Pass" mode, rotate the valve handles so that the arrows

point toward each other.

Dry Mode

By-Pass Mode

Figure 2b – Air Bypass Assembly

Models 20 through 50