4

3.0 Installation

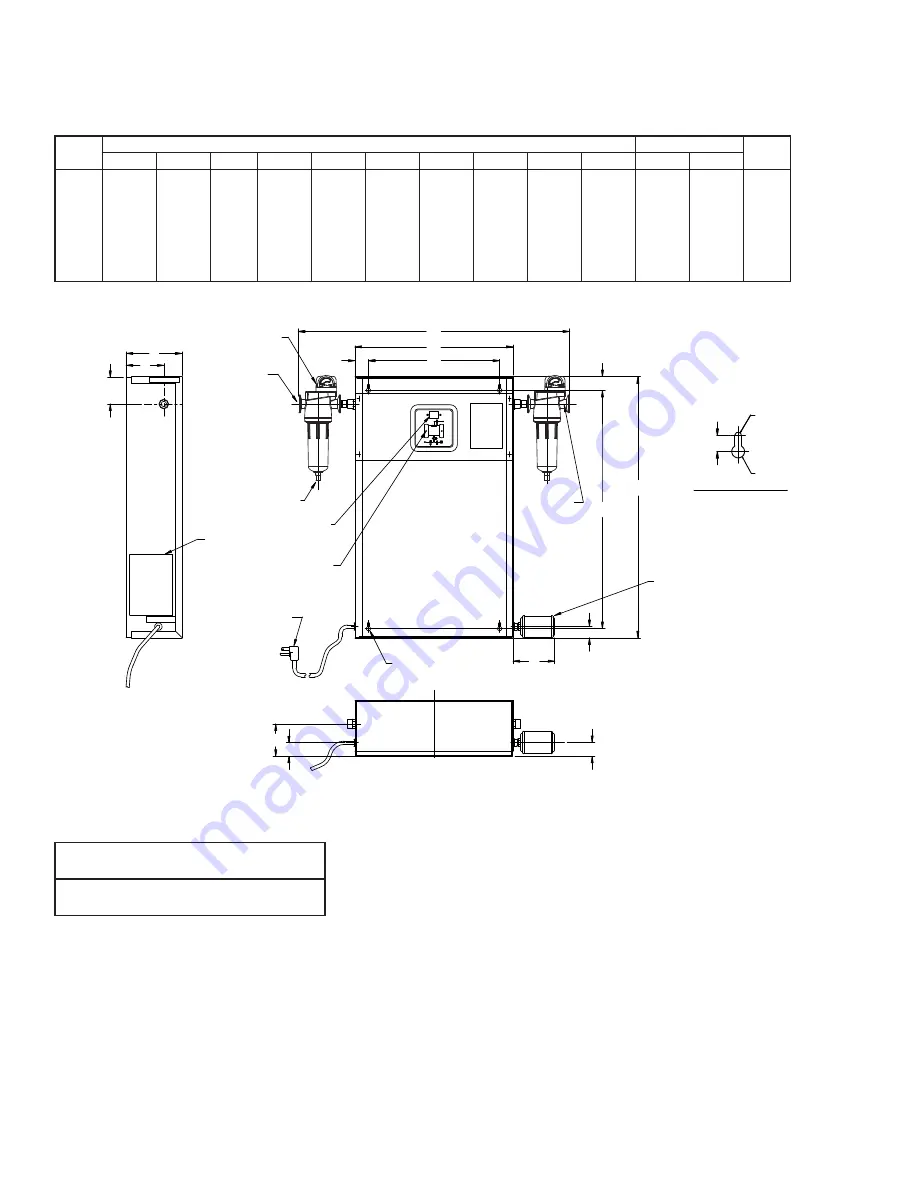

3.1 Dimensions, Connections, Weight

Maximum Operating Pressure:

150 psig, 10.5 kgf/cm

2

Maximum Operating Temperature:

120°F, 49°C

MODEL

NUMBER

DIMENSIONS in (mm)

CONNECTIONS

WEIGHT

lb (kg)

A

B

C

D

E

F

H

J

K

M

INLET

OUTLET

7

13

20

25

30

35

50

31.09 (790)

31.09 (790)

31.09 (790)

37.94 (964)

37.94 (964)

37.94 (964)

37.94 (964)

17.52 (445)

17.52 (445)

17.52 (445)

24.37 (619)

24.37 (619)

24.37 (619)

24.37 (619)

1.15 (29)

1.15 (29)

1.15 (29)

1.68 (43)

1.68 (43)

1.68 (43)

1.68 (43)

15.23 (387)

15.23 (387)

15.23 (387)

21 (533)

21 (533)

21 (533)

21 (533)

6.69 (170)

6.69 (170)

6.69 (170)

8.54 (217)

8.54 (217)

8.54 (217)

8.54 (217)

3.74 (95)

3.74 (95)

3.74 (95)

6.73 (171)

6.73 (171)

6.73 (171)

6.73 (171)

30.5 (775)

30.5 (775)

30.5 (775)

31.6 (803)

31.6 (803)

31.6 (803)

43.3 (1100)

3.74 (95)

3.74 (95)

3.74 (95)

4.25 (108)

4.25 (108)

4.25 (108)

4.25 (108)

5.31 (135)

5.31 (135)

5.31 (135)

6.22 (158)

6.22 (158)

6.22 (158)

6.22 (158)

27.5 (699)

27.5 (699)

27.5 (699)

27.5 (699)

27.5 (699)

27.5 (699)

39.3 (998)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

55 (25)

60 (27)

71 (32)

93 (42)

93 (42)

99 (45)

132 (60)

SEE MOUNTING

SLOT DETAIL

6' POWER CORD

(SEE NOTE 1)

ELECTRICAL ENTRY

ON/OFF

SWITCH

TOWER

INDICATING

LIGHTS

BACK OF ENCLOSURE

MOUNTING SLOT DETAIL

PURGE

MUFFLER

1/4" R.

5/8"

1.69

(43)

1/8" R.

FIELD MOUNTED

PREFILTER

INLET

FIELD MOUNTED

AFTERFILTER

OUTLET

AIR INLET

H

M

E

F

2.46

(62.5)

INSTRUCTION

TAG

C

D

B

A

SERIAL

NO.

TAG

(INSIDE

COVER)

F

J

2.36

(60)

K

2.36

(60)

AUTOMATIC DRAIN

DIFFERENTIAL PRESSURE

INDICATOR

P1

P2

Figure 3 Dimensional Drawing

NOTE:

1. Dimension "A" applies only to units equipped

with optional prefilter and afterfilter package.

Specific dimensions of filters available upon

request.

2. Connection sizes valid with or without filters.

3. Weight applies to unit only, add 6-1/2 lbs.

(3 kg) to weight for optional filter package

when specified.