17

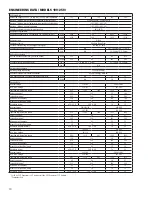

Drain Alarm #2 Input

13

21

W3

6

W2

8

W3

7

W3

4

W3

2

W3

0

FMD #1 In (RJ-11)

FMD #2 In (RJ-11)

J2 RS-232

RE

D

BL

AC

K

WHITE

22

21

20

19

18

17

16

15

14

W3

8

Evaporator Ther

mistor

Evaporator Ther

mistor

Phase B xfmr Inpu

t

Phase A xfmr Input

Phase Com.

xfmr Input

W4

N/A

N/A

W7

W6

W5

N/A

W3

5

Gn

d.

(W

28 thru W32)

Remote/L

ocal Input

Remot Star

t/Stop Input

N/A

N/A

W3

3

W3

1

N/A

N/A

N/A

W2

9

W12

30

37

35

36

34

35

34

33

32

31

TC

I

TB2

TB2

25

29

28

27

26

28

27

26

24

23

22

23

22

TB2

28

26

27

EMM INSTRUMENT BO

AR

D

W20

W2

4

W2

6

W2

2

12

11

10

09

07

08

06

05

04

Gnd

(W

8 thru W14)

Drain Alarm #1 Input

Lo

w

Pr

essure Sw

. Input

Heater #1 ON Input

High

Pr

essure Sw

. Inpu

t

Alarm A Com.

Co

mpressor #1 ON Inpu

t

Alarm A N/

C

Alarm A N/

O

W15

W13

W14

W11

W10

W9

W8

W21

W19

Alarm B N/C

Alarm B Com.

Drain T

est Output

Alarm B N/

O

Drain T

est Output

Co

mpressor #1 Outpu

t

Co

mpressor #1 Outpu

t

W2

7

W18

W17

W1

6

N/A

N/A

W2

5

W2

3

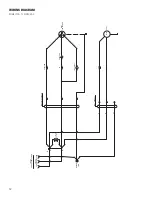

FROM SHEET 01

01

03

02

00

Chassis Gn

d.

TB2

X

24V

AC

IN

24V

AC

IN

W3

W2

W1

X

TB2

3X

REMOVE JUMPER IF OPTIONAL DRAIN INST

ALLE

D

-4NO

TB2

TB2

TB2

TB2

TB2

19

20

21

18

17

19

20

21

18

17

14

16

15

13

12

14

16

15

13

12

16

TB2

TB2

TB2

20

18

19

17

TB2

TB2

14

12

15

15

13

TB2

TB2

TB2

10

11

9

8

10

11

9

8

7

6

4

5

7

4

TB2

TB2

10

8

11

9

TB2

4

7

X

-3NO

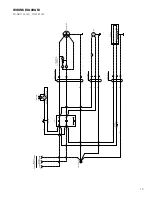

CO

NT

1

19

16

-1NC

20

19

18

17

CO

NT

1

-2NC

19

4

8

7

BL

U

TB2

CO

NNECT

OR

PE

2

1

PE

2

1

PE

BR

N

RED

BR

N

F1

LO

AD

LINE

WHITE

PE

BL

U

TERMINAL BL

OCK LA

YO

UT

TB2 19

18

19

TB2

HPS/LPS SENSOR HARNES

S

17

19

HPS

TB1

LPS

HP

S

L1

L1

8

X

X

4

N

X

X

N

N

N

4

4

4

8

7

7

19

15

11

10

9

14

13

12

18

17

16

19

19

19

26

21

20

28

27

PE

PE

PE

PE

L3

L2

PE

L3

L2

PE

4

6

3

1

1

3

6

4

TB2 19

TB2

PE

OPTIONAL DRAIN

DRAIN 2 HARNESS

X

N

20

19

7

8

5

3

2

8

7

19

20

N

X

5

3

2

DRAIN 1 HARNES

S

4

24V

AC

AL

M

TEST

TEST

AL

M

24V

AC

CO

NT

AC

TO

R

CO

MPRESSOR

CO

NT

1

A1

A2

N

FROM SHEET 01

TB2

N

BLAC

K

WHITE

(Mounted in Enclosure)

DB9 MALE C

ONNEC

TO

R

3

8

9

5

RED

4

6

7

21

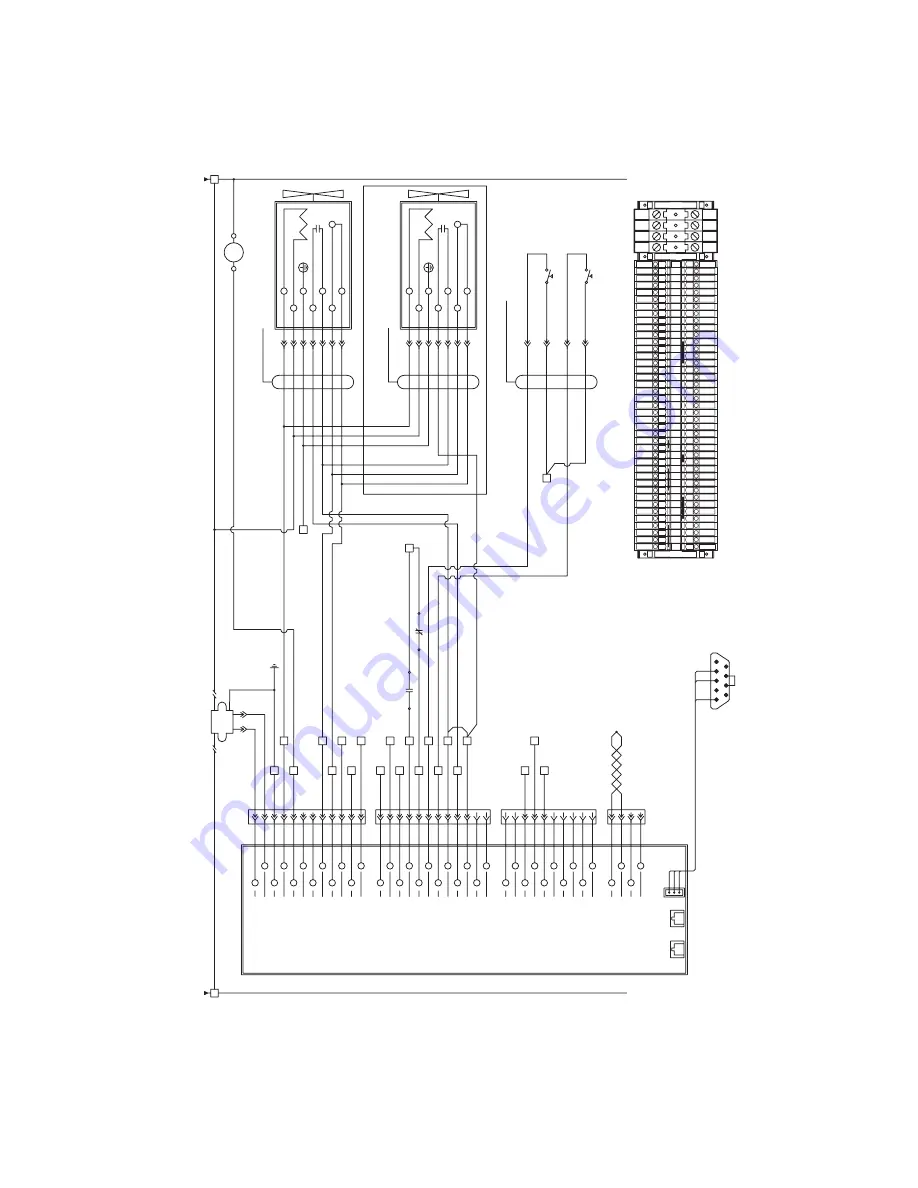

WIRING DIAGRAM

Model 750, (460 VAC)

Sheet 2 of 2