5

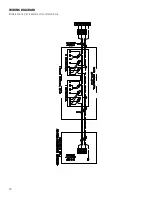

1.6 Operation

A. Verify that isolation valves are open. If the drain fails to

discharge after the valve is energized, the electronic

control circuit will repeatedly energize the valve in an

attempt to clear the discharge port. If, after 60 seconds,

the drain still fails to discharge, the control circuit then

switches to the alarm mode. In this mode the valve is

de-energized and the red alarm light is activated on

the drain and the dryer controller. The valve is then

automatically energized every 4 minutes for 5 seconds.

Check the drain operation. Push drain (push-to-test)

button on the Energy Management Monitor control

board to energize drain. A flow of condensate and/or air

should be present at the drain outlet. The alarm mode

automatically clears after the drain returns to normal

operation.

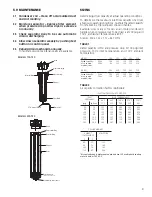

B. Condensate enters the reservoir

(1)

through the inlet

port. When the condensate level in the reservoir covers

the capacitance sensor, an electronic signal is sent to the

solid state countdown processor. The processor delays

the opening of the solenoid valve for a given period

of time. Once the time has elapsed, the solid state

processor transmits information to energize the coil in

the solenoid valve

(2)

. The magnetic force of the coil

causes the solenoid core

(3)

to move, closing the pilot

air supply line and opening the pilot air exhaust line.

After the pilot air above the diaphragm

(4)

is vented,

pressure in the reservoir opens the discharge port and

forces the condensate through the discharge port and

outlet piping.

2.0 OPERATION

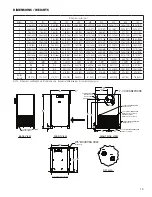

2.1 Minimum/Maximum operating conditions

A.

Maximum inlet air pressure: refer to dryer serial number

tag

B. Minimum inlet air pressure: 30 psig (2.1 kgf/cm

2

)

C. Maximum inlet air temperature: 120°F (49°C)

D.

Maximum ambient temperature:

Air-cooled models: 110°F (43°C)

Water-cooled models: 130°F (54°C)

E. Minimum ambient temperature: 40°F (4°C)

2.2 Start-up

A.

Models 100-150:

Energize compressor by positioning the on/off switch in

the on (I) position. Compressor on light will illuminate.

On/Off Switch

Power-On Light Dewpoint Indicator (Green)

B.

Models 200-750:

Energize dryer. Green power on light will illuminate.

IMPORTANT: Energize dryer disconnect switch (provided by

others, see NEC) 24 hours before refrigeration compressor

is started! Never use the disconnect switch to shutdown

the dryer for a extended period of time (except for repair).

Failure to follow these instructions may result in a non-

warrantable compressor failure.

NOTE: If there is no power to the control board for a period

of two weeks or more, it may return to the default mode.

C.

Program Monitor

Press and hold Program Mode button until Main Menu screen

appears. Use the Up and Down arrow buttons to scroll

through the list of submenu choices. Press Enter button

to view the submenu that is displayed. Press ESC to exit the

Main Menu and return to Display mode.

1. Language selection

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll

through the list of languages (choice of 10 available:

English, Deutsch, Francais, Espanol, Italiano, Polski,

Dansk, Dutch, Norsk and Suomi).

b. Press ‘Enter’ button to select the language that is

displayed.

c. Push ‘ESC’ at any time to return to the Main Menu.

2. Setting Date & Time

a. Use the ‘Up’ and ‘Down’ arrow buttons to set minutes

(00 to 59). Press ‘Enter’ to accept new value.

b. Use the ‘Up’ and ‘Down’ arrow buttons to set hours

(00 to 23). Press ‘Enter’ to accept new value.

c. Use the ‘Up’ and ‘Down’ arrow buttons to set year

(00 to 99 representing 2000 to 2099). Press ‘Enter’

to accept new value.

d. Use the ‘Up’ and ‘Down’ arrow buttons to set month

(three letter abbreviation). Press ‘Enter’ to accept

new value.

e. Use the ‘Up’ and ‘Down’ arrow buttons to set day

(01 to maximum for the month and year selected).

Press ‘Enter’ to accept new value.

f. Push ‘ESC’ at any time to return to the Main Menu.

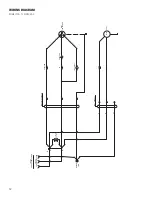

1

2

3

4