8

F.

Using the RS-232 port

The RS-232 port is used to monitor dryer operation from a

host computer. A (1 to 1) DB-9 cable is required to connect

dryer and computer. For PC connections, data is transmitted

on pin 2, received on pin 3, ground is pin 5, pins 7 and 8 are

jumpered at dryer.

Operation is at fixed baud rate of 9,600; asynchronous format

is 8 bit, no parity, 1 stop bit (“8,N,1”). No check sum or error

correction values are provided. If required, request status

string two (or more) times and compare for agreement.

Request data by sending ASCII ? character (3FH). Response

may take up to two seconds as certain processing functions

may require completion before serial port is acknowledged.

Dryer responds with line feed (0AH), carriage return (0DH),

and character string: (1), (2), (3), (4), (5), (6), (7), (8), (9)

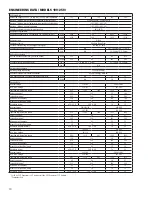

(1) = STX (start-of-text character, may appear as a smiley

face or some other character

(2) = 108, Control board ID

(3) = 0 or 1, Compressor running status (0=off, 1=on)

(4) = M or S, Operating Mode (M= MANUAL OVERRIDE, S

= SCHEDULE RUNNING)

(5) = xxxx, HOURS TO SERVICE

(6) = xxxxxx, TOTAL HOURS

(7) = xx, Alarm or Service Code (0=no alarm, 30=LOW

PRESSURE ALARM, 31=HIGH PRESSURE ALARM,

32=COMPRESSOR ALARM, 36=HIGH EVAP TEMP ALARM,

37=HEATER ALARM, 38=DRAIN ALARM, 39=SERVICE

DRYER, 41=TEMP SENSOR ALARM)

(8) = xx.x, Evaporator temperature (°F)

(9) = ETX, (end-of-text character, may appear as a heart

or some other character)