Parts List & Operating Instructions

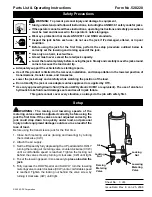

Air can accumulate within a hydraulic system during shipment or after prolonged use. This entrapped air causes

the jack to respond slowly or feel “spongy.” To remove the air:

1. Tilt the jack onto two casters with the pump handle positioned below the cylinder.

2. Open the release valve by turning the knob counterclockwise (CCW).

3. Pump the handle until resistance is felt.

4. Close the release valve by turning the knob all the way clockwise (CW).

5. Continue pumping the handle while returning the jack to its upright position.

Form No. 528220, Back of Sheet 3 of 4

Bleeding Air from the Hydraulic System

Operating Instructions

This is a two-stage transmission jack. The air stage is designed to quickly move the adapter into position, and

is completed with an automatic lock function that prevents loss of load. The next hydraulic stage is designed

to align the adapter with the transmission.

WARNING: PERSONAL INJURY AND/OR EQUIPMENT DAMAGE MAY OCCUR IF THE SETUP

PROCEDURE (SHEET 3, FRONT) IS NOT PERFORMED. The raising and lowering speed of the metering

valves must be adjusted correctly before using the jack the first time. If the valves are not adjusted

correctly, the jack could drop down too quickly under load, and personal injury could occur as a result

of the loss of load.

1. Lift the vehicle on a hoist.

2. Position the jack under the transmission.

3. Connect the shop air supply to the jack. (90 psi of clean, dry air is required for the capacity of this jack.)

4. Press the pedal marked UP to raise the adapter until the cylinder locks into place (at about 20 inches). The

air hose can be removed at this time.

WARNING: If a load is transferred to the adapter when the air cylinder is only partially raised, the

cylinder will drop suddenly. To eliminate this problem, always raise the cylinder to the point where the

mechanical lock engages.

5. Check the placement of the jack. The transmission’s center of weight, or balance point, should be centered

over the jack adapter, with the power output end located over the adapter bracket between the chains. The

jack’s mechanical lock must be engaged.

6. Close the hydraulic release valve by turning the knob clockwise (CW).

7. Pump the jack handle to finish raising the adapter to the transmission. Use the controls on the adapter to roll

or tip the adapter as needed to align it with the transmission.

8. Push in the four adapter brackets until they touch the transmission. Use the chains to secure the transmission

to the adapter.

9. Support the engine, and remove the transmission according to instructions in the vehicle service manual.

10. Slowly turn the hydraulic release valve counterclockwise to lower the hydraulic stage. Lower the air stage

by pressing the DOWN foot pedal. If the load is already resting on the mechanical lock, attach the air hose,

and press the UP pedal briefly so the mechanical lock will release. The air stage should then lower when the

DOWN pedal is pressed.