English Manual

Page 6

1019501-B

Use and Care

CalibraTion

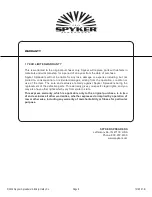

1. Measure a distance of 25 feet on grass or another

surface that will prevent the spread particles from

bouncing (such as a large blanket or loose dirt) and mark

a start and finish line.

* NOTE: If the scale reports weight in pounds and

ounces, see appendix A (below) to convert to pounds.

6. Measure in feet the total width of ground that the material

covers. Subtract 4 feet and record this value as the

Spread Width.

SPReAD WIDTH

________ ft

3. Set the calibration knob to the setting that corresponds to

the material most similar to the material you are trialing.

4. Begin to spread material while walking down the track at

a speed of 3 MPH. Turn the crank one full rotation every

other step.

5. Weigh the spreader and record the weight in

pounds as Final Weight.

FINAl WeIGHT

________ lbs

INITIAl WeIGHT

________ lbs

2. Fill the bag approximately 3/4 full & weigh the spreader.

Record this weight in pounds as Initial Weight.

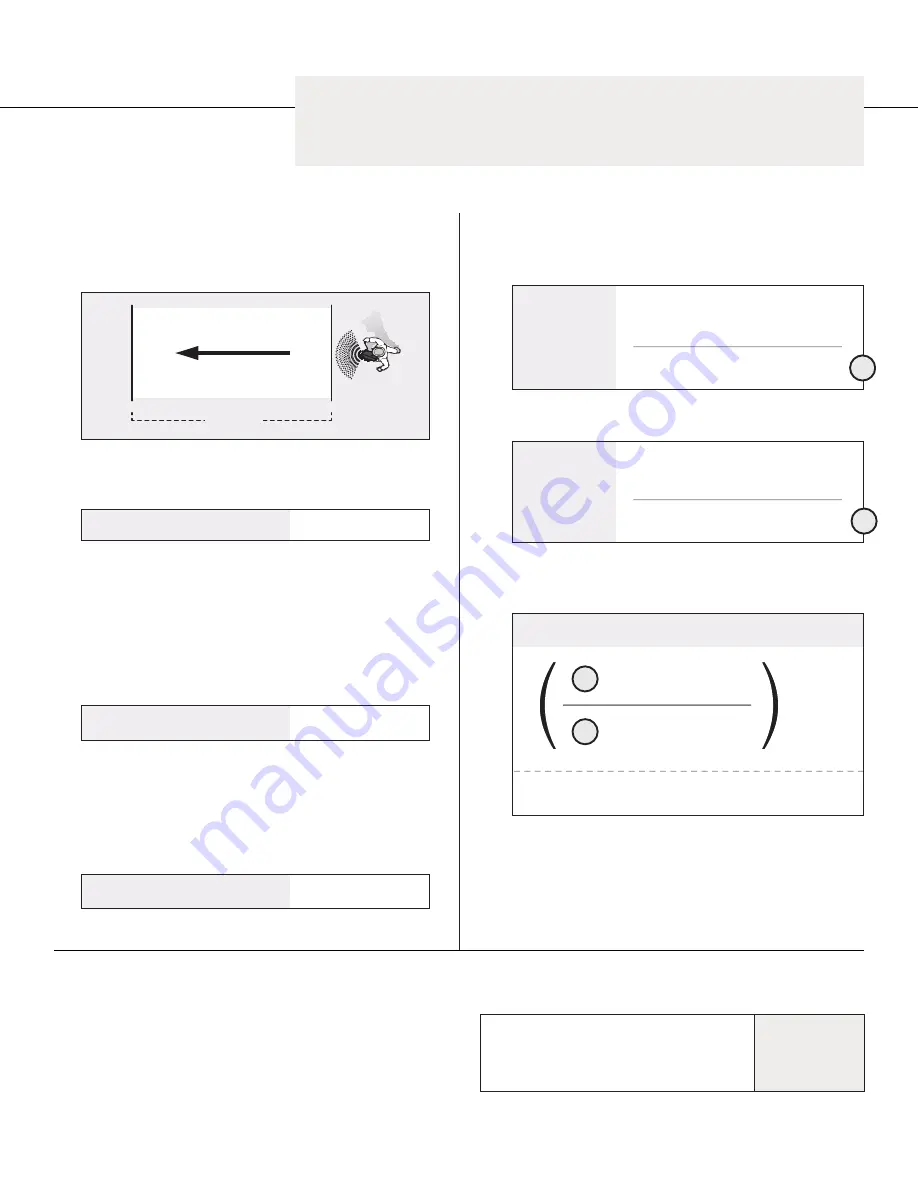

7. Calculate the actual application rate

using the following formulas:

8. Determine the weight of the material spread in pounds:

HOW TO

CAlCulATe

MATeRIAl

SPReAD

Initial Weight ______ lbs

- Final Weight ______ lbs

= Material Spread ______ lbs

A

HOW TO CAlCulATe APPlICATION RATe

= Application Rate ______ lbs/1000 sq ft

Material

Spread

Area

Covered

______ lbs

______ ft

A

B

x 1,000

10. Lastly, calculate the application rate in pounds per 1000

square feet:

* NOTE: To calculate the rate in lbs/acre instead

of lbs/1000 sq ft, multiply the (A/B) value by 43,560.

9. Next, find the area covered in square feet:

HOW TO

CAlCulATe

THe AReA

COVeReD

Spread Width ______ ft

x Length of Track 25 ft____

= Area Covered ______ ft

B

FINISH

ST

ART

25

ft

(The number

12 represents

the ounces)

Appendix A:

Converting pounds-ounces to pounds.

Scales will often report weight in pounds and ounces

instead of just pounds. Use the steps below to convert to pounds.

1. Determine the ounces value on the scale. . . . . . . . . . . . . . . . . . . . . . . . .

example:

10 lbs - 12 ounces.

2. Divide the ounce value by 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

example:

12 ÷ 16 = 0.75

3. This decimal will be the decimal value of the weigh in pounds.

Use the weight in pounds for calculate application rate.

example:

10lbs - 12 ounces = 10.75lbs

The goal is to determine which setting on the calibration knob will correspond to the

recommended application rate for the material being spread. The application rate

will be printed on the bag or container that the material was supplied in. Locate the

application rate before proceeding with the calibration trial.