1008198 Rev. B

6

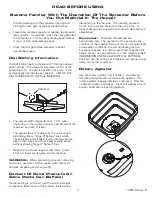

READ BEFORE USING

OPERATE SAFELY

Keep bystanders away when you operate this machine.

Use this machine for intended purpose only.

Do not let children or an untrained person operate

machine.

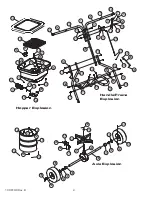

Keep all parts in good condition and properly installed.

Fix damaged parts immediately. Replace worn or broken

parts.

Do not modify the machine or safety devices.

Unauthorized modifications to the machine may impair

its function and safety, and void the warranty.

Do not let anyone sit or ride on equipment during

operation. Keep riders off attachment.

Wear substantial footwear and long trousers. Do not

operate the equipment when barefoot or wearing open

sandals.

Do not wear loose fitting clothing that can get caught in

moving parts.

Always wear eye protection when operating the

equipment.

Stay alert for holes in the terrain and other hidden

hazards.

Watch out for traffic when crossing or near roadways.

Before you operate any feature of this machine, observe

your surroundings and look for bystanders.

Always wash hands after contact with fertilizers and

pesticides.

Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition.