1007895 Rev. D

4

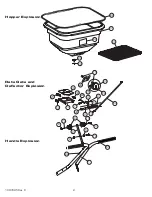

Item Part Number

Qty Description

1

1007770-01

1

Handle Stainless

1008052-10

1

Handle Painted

2

1007773

1

Control Lever

3

05-90-0054

12 1/4" x 1-1/2" Bolt, SS

4

05-92-0008

6

1/4" Washer, SS

5

05-94-0051

2

Nylon Flange Bushing

6

SS-91-0004

17 1/4" Nylon Locknut, SS

7

05-90-0121

1

1/4" x 3/4" Bolt, SS

8

1007828

2

Knob Half

9

1007774-01

1

Axle Support Stainless

1008055-10

1

Axle Support Painted

10

1007777-01

1

Hopper Support Stainless

1008058-10

1

Hopper Support Painted

11

1007794

2

Cross Brace Stainless

1008061-10

2

Cross Brace Painted

12

1007811

1

Control Linkage Assembly

13

1007888

2

1/4" x 2-1/4" Bolt, SS

14

SS-92-0002

2

Felt Washer

15

05-94-0078

2

Pine Tree Clip

16

SS-96-0003

1

Agitator Wire

17

05-94-0043

1

Accuway® Diffuser

18

05-94-0064

5

Nylon Washer

19

05-94-0097

2

Rate Gate Guide

20

05-48-1015

1

Dial Mount Retainer

21

05-46-2211-T

1

Accuway® Screw

Assembly

22

05-48-1113-T

1

Rate Gate & Dial Assy

23

SS-94-0006

1

Plastic Dial

24

1008431-01

1

Rate Gate Link

25

05-94-0099

1

Dial Mount

26

05-94-0068

1

Rate Gate

27

1007847

1

Hopper

28

F-574

1

Bearing

29

B1HF577

1

5/8" E-Ring

30

N/A

Number Not Used

31

N/A

Number Not Used

32

N/A

Number Not Used

33

05-90-0102

1

Hairpin Cotter, SS

34

N/A

Number Not Used

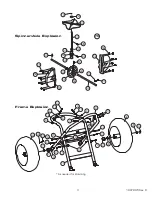

Item Part Number

Qty Description

35

N/A

Number Not Used

36

N/A

Number Not Used

37

N/A

Number Not Used

38

N/A

Number Not Used

39

N/A

Number Not Used

40

05-90-0065

1

3/16" x 1-3/4" Clevis

Pin

41

05-92-0004

3

Flat Washer, SS

42

05-95-0016-JD

2

Wheel

43

05-90-0040

1

Rue Ring Locking Pin

44

SS-94-0012

1

Spreading Spinner

45

SS-90-0002

1

1/8" x 7/8" Roll Pin

46

N/A

Number Not Used

47

05-97-0037

1

Spinner Shaft, SS

48

SS-90-0001

1

1/8" x 3/4" Roll Pin

49

05-90-0093

2

5/8" Gearbox Bushing

50

05-90-0094

2

3/8" Spinner Shaft

Bushing

51

05-90-0096

1

3/16" x 1" Dowel Pin, SS

52

05-94-0033

1

Bevel Gear

53

05-94-0034

1

Pinion Gear

54

05-288-1027

1

Nylon Spacer Retaining

Pin

55

05-90-0097

8

#10 x 5/8" Flanged

Head Bolt, SS

56

05-91-0008

8

#10 Nylon Locknut, SS

57

05-94-0037

1

Gear Box Cover Front

58

05-94-0038

1

Gear Box Cover Rear

59

05-98-0111

1

Grease Zerk

60

1007781

1

Axle

61

F-283

2

Axle Bearing

62

05-94-0065

1

Hopper Cover

63

1008022

1

Screen

64

05-46-1014

1

Control Rod

65

SS-94-0013

2

Handle Grip

66

N/A

Number Not Used

67

N/A

Number Not Used

68

05-99-0063

1

On-off Decal

69

05-93-0075

1

Spyker Accuway® Label

70

1007818

1

Spinner/Axle Assembly

71

N/A

Number Not Used

72

1001255

2

1/4" x 1" Bolt, SS

73

1001554

2

Nylon Washer