1007895 Rev. D

9

READ BEFORE USING

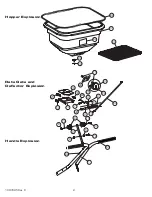

Now You Are Ready To Put

Material In The Hopper

WARNING:

Avoid Injury! Chemicals can be

dangerous. Avoid injury to operators or bystanders.

• Make sure the rate gate is in the closed position.

• Read chemical container label for handling

instructions. A Material Safety Data Sheet (MSDS)

should be supplied by the chemical dealer and

provides proper safety information.

• Wear proper clothing and safety equipment while

handling or applying chemicals.

• Prohibit all smoking, drinking, and eating around

chemicals.

• When spreading products containing herbicides,

exercise extreme caution with respect to careless

spreading and to wind-drift. Contact Of Some

Products On Some Plants Can Be Fatal.

• Fill the spreader on a fl at, level surface only. Fill on

sidewalk, driveway, cardboard, etc. to avoid material

loss.

• When

fi lling hopper with material, always use screen

to help break up clumps.

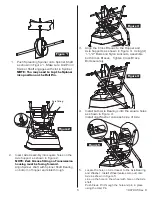

Now You Are Ready To Spread

• Keep spinner blade clean. Excess material build-up

can cause an uneven spread pattern.

• Keep the impeller level when spreading.

• DO NOT overload. Maximum capacity is 50 lbs.

• DO NOT use on windy days.

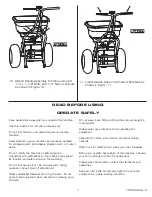

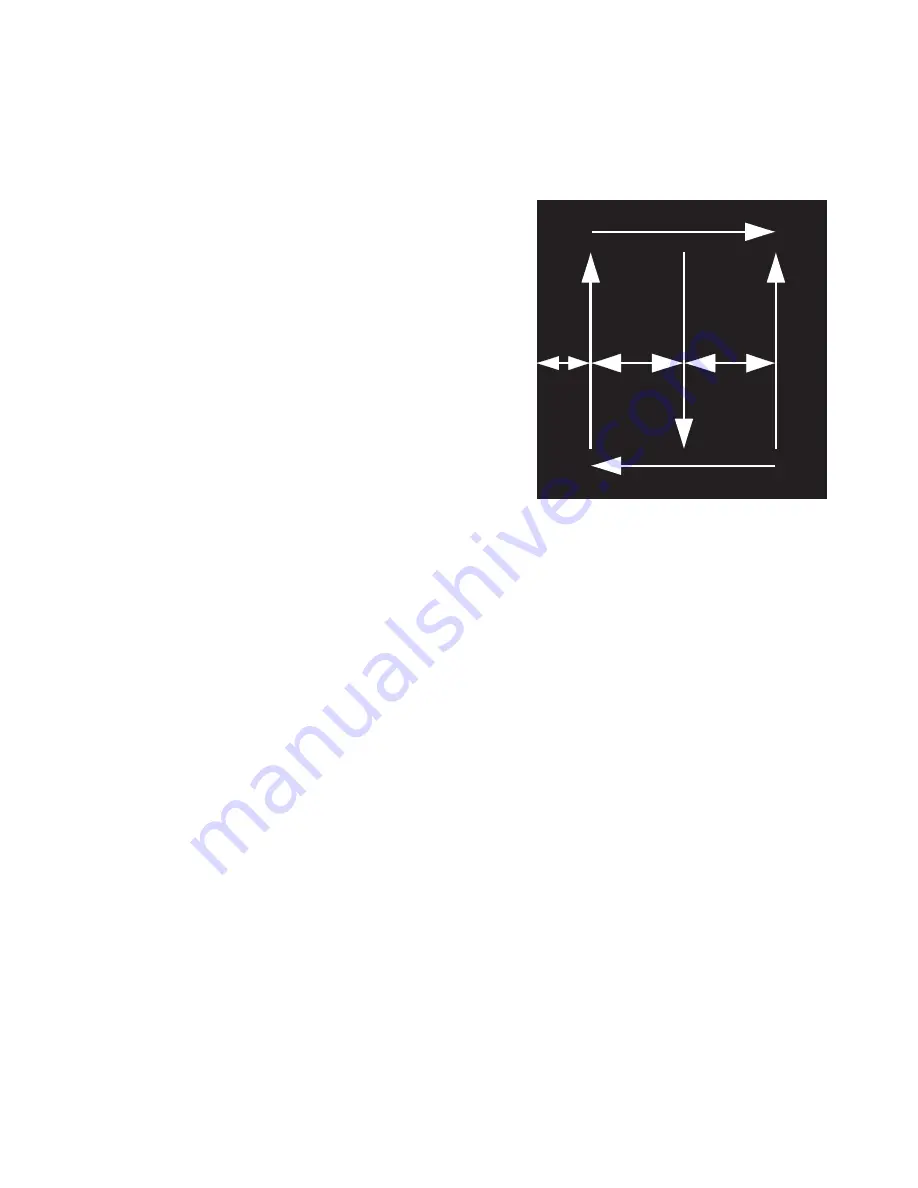

• Spread header strips at the ends of the area

OPPOSITE of the direction of spreading. This will

provide a "turn-around" area, an area to re-align the

spreader for the return spread.

• Example shown is for 6 ft. wide spread. Make the

fi rst spread pass at one-half the spread width from

the edge of the spreading area or in this case,

approximately 3 feet (or one big step).

• Additional spreading passes will be at the full spread

width or approximately 6 ft. apart.

• TAKE A SIGHTING AT THE FAR END. Keep your eye

on the sighting as you spread. You will not need

to wonder where you are or where you have been.

Continue until spreading is completed.

• Left over fertilizer can be spread under trees and

other high feeding areas without showing "edge of

spread" lines.

Tip:

When not spreading, and if pushing the spreader

some distance, tip the spreader so only the idle wheel is

on the ground.

Header

6’

6’

3’

Header

Cleaning The Spreader Is Part

Of The Spreading Job

Clean and oil spreader immediately after each use.

Method #1 - Wipe spreader thoroughly with an oily cloth.

Oil all bearings and bearing areas.

Method #2 - Wash, rinse, and dry the spreader. Note:

Drying takes time. Moisture trapped in bearing areas is

slow to go. Immediately after drying - oil all bearings and

moving parts. Make certain all operations are thorough.

NOTE: Good "Dry Cleaning" is preferable to poor "Wet

Cleaning".

• It is virtually impossible to have rust and corrosion on

a clean, dry, oiled surface.

• Again - just before using - oil all bearings and moving

parts.

• In storage, ideally the spreader should be hung by

the handle. In any case, do not pile weight on the

spreader, as excess weight over a period of time can

distort the tires.

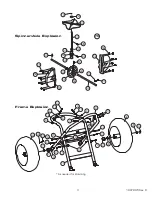

Oil Bearings And All Moving

Parts

Make sure the spreader is running freely!