©2016 Spyker Spreaders/A Brinly-Hardy Co.

11

1017459 Rev. A

Maintenance

6. Check the fuel level, the engine oil level & clean the

cooling-air intake.

7. Clean air cleaner element.

8.

After the first 5 hours of use, change the engine oil.

(Change the oil every 50 hours thereafter).

9. Follow the Maintenance Table found in the engine

manual.

10. Place the machine in locked storage to avoid

tampering or use by an untrained operator. Do not

store near flame.

C. MAINTENANCE EVERY 50 HOURS

1. Change the engine oil. (Change the engine oil more

frequently under severe operating conditions).

2. Clean spark plug and check the spark plug gap.

3. Clean air cleaner element.

4. Check that all nuts, bolts and screws are tight.

5. Check the condition and tension of trans-axle belt.

The idler pulley should be adjusted so that a 5 lb.

pull on the belt between the engine pulley and the

pump pulley deflects the belt about 3/16”.

NOTE

: It may be necessary to remove the skid plate

and skid plate hardware to properly adjust the

idler pulley. If the skid plate is removed, save

the hardware and skid plate for replacement

after the adjustment is complete.

A. GENERAL MAINTENANCE

1. Never allow untrained personnel to service machine.

2. If the machine must be tipped on its side for

maintenance, do not tip more than 45 degrees.

This will prevent hydraulic oil from draining out of

the Transmission Hydraulic Tank Breather Cap.

Before tipping machine, drain the fuel from the fuel

tank, and the oil from the engine’s crankcase.

3. Be careful not to spill oil on any of the belts.

4. Ensure unit is properly supported by jack stands.

5. Do not tamper with the engine’s governor settings.

They are adjusted to provide the proper maximum

engine speed.

6. If the machine is to be in storage for more than 30

days, drain the fuel tank, run the engine to drain the

carburetor dry, change the oil, remove the spark

plug and pour a teaspoonful of oil into the cylinder.

Pull the starter rope briefly to crank the engine and

distribute the oil, then replace the spark plug.

7. Keep all parts in good working condition & all hardware

tightened. Replace all worn or damaged decals.

B. DAILY MAINTENANCE & STORAGE

AFTER SPREADING

1. Park the machine on level ground outside the storage

facility with the engine shut off.

2. Close the fuel shutoff valve.

3. Permit the machine to cool.

4. Disconnect the spark plug wire.

5. Wash the machine off with water. Be sure to clean out

materials from under the hopper. Allow the machine to

dry before storing.

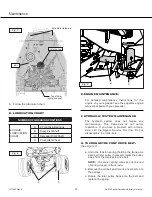

WARNING:

AVOID INJURY!

DISCONNECT THE SPARK PLUG WIRE TO PREVENT THE ENGINE

FROM ACCIDENTALLY STARTING BEFORE PERFORMING ANY MAINTENANCE ON THIS MACHINE.