©2016 Spyker Spreaders/A Brinly-Hardy Co.

9

1017459 Rev. A

C. BREAK-IN AND OPERATION

1. Make certain you thoroughly understand all of the

safety precautions before you attempt to operate

this machine.

2. CHECK THE ENGINE OIL LEVEL.

Do not screw in oil dipstick to oil filler neck to check

oil level. See Engine Manual. Fill to the proper

level with SAE 10W-30 engine oil. Tighten oil

gauge to filler neck when done.

3. MOVE THE MACHINE OUTDOORS

Check the engine gasoline level. When filling the

tank, stop when the gasoline reaches one inch

from the top. This space must be left for expansion.

Use fresh, clean, unleaded, regular gasoline.

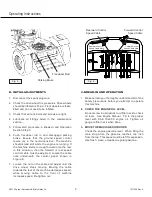

B. INITIAL ADJUSTMENTS

1. Disconnect the spark plug wire.

2. Check the drive wheel tire pressures. Drive wheels

should be inflated to 15 psi. Front wheels are foam-

filled and do not need to be inflated.

3. Check that all nuts, bolts and screws are tight.

4.

Lubricate all fittings listed in the maintenance

section.

5. Follow start procedure in Break-In and Operation

Section Step 5.

6. Push freewheel rod in and disengage parking

brake. Ensure that the ground speed control

levers are in the neutral position. The machine

should stand still while the engine is running. If

the machine starts to creep forward or to the rear

in this situation, then the forward or rear speed

control cable must be adjusted. Locate the cable

nuts underneath the control panel shown in

Figure 6.

7. Loosen the nut on the cable and adjust until the

drive wheel stops moving. Moving the cable

towards the rear of the machine decreases speed,

while moving cable to the front of machine

increases speed. Re-tighten nut.

Operating Instructions

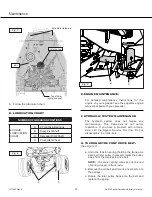

Fig. 5

Fig. 6

Rearward Control

Speed Cable

Rearward Control

Speed Cable Nuts

Forward Control

Speed Cable Nuts

Forward Control

Speed Cable

Freewheel Rod

Parking Brake