Page 11

English Manual

1019622-C

Assembly

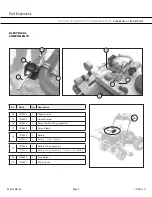

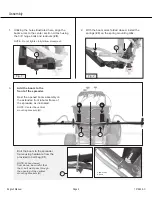

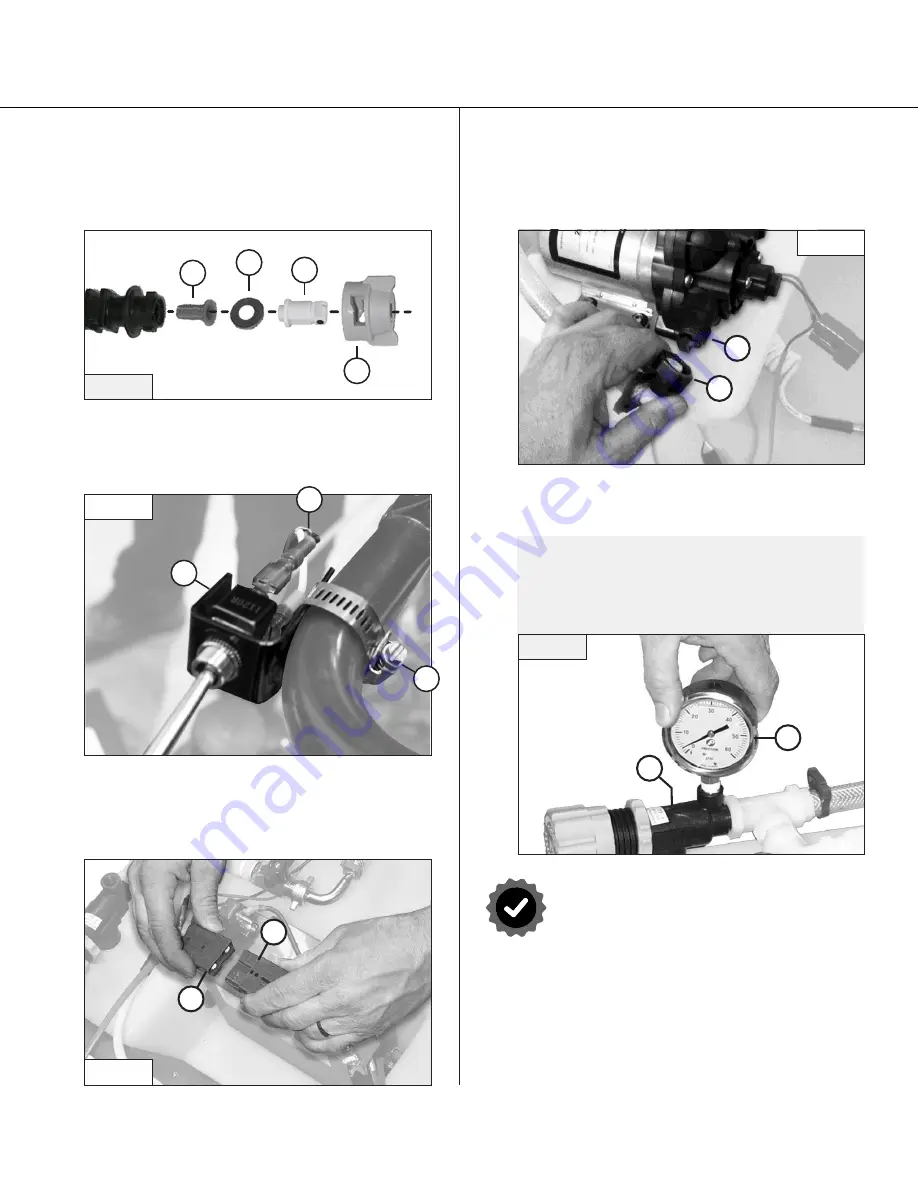

10. Connect swivel elbow fitting (

42

) to the pump inlet

port (

41

).

Fig. 10

CAUTION!

Screw in the gauge hand-tight,

with only sufficient force to prevent leaking.

Overtightening the gauge can break the

regulator housing (33).

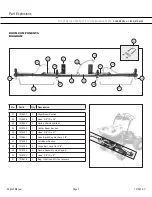

Fig. 11

11. Install the pressure gauge (

34

).

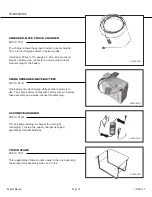

7. Install the sprayer nozzles (

54

), screens (

56

),

washers (

57

) and caps (

55

).

Assembly is complete.

41

42

34

33

8. Install the handle thumb switch (

15

) with a screw

clamp (

17

). Plug in the switch wiring (

16

).

16

17

15

Fig. 8

Fig. 7

56

57

54

55

Fig. 9

19

19

9. Install the pump wiring assembly clips to

the switch spades and connect the battery wiring

assembly (

19

).