Page 12

English Manual

1019622-C

Use and Care

!

READ BEFORE USING

GENERAL OPERATION &

MAINTENANCE

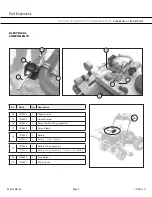

The sprayer pump is turned on and off by the thumb

switch mounted on the handlebar of the spreader. Each

dripless nozzle body has a special shut-off cap. The

nozzle body requires 5 psi of system pressure to open,

thus keeping the nozzles from dripping when the pump

is off. The nozzles can be completely shut off by turning

the cap clockwise. The operator can turn off individual

nozzles as needed. The hand spray wand is activated

by closing the boom line valve (ball valve on top of the

tank) to turn off flow to the boom. To drain the tank of

unused liquids, remove the spray tip from the wand and

pump the remaining liquid into the proper receptacle.

• Clean pump filter daily.

• Clean tip screens regularly.

• Prevent from freezing.

• Adjust hinge lock nut tension as necessary.

• Flush with water after each use.

• Lubricate hinges with grease.

INITIAL START-UP

& PRESSURE TESTING

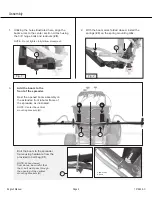

1. Turn the pressure regulator knob counter-

clockwise all the way.

2. Put about one gallon of water in the tank for

testing.

3. Be sure that the spray line valve is turned off.

4. Turn on the handlebar thumb switch. You should

hear the pump running and see water moving

through the hoses.

5. Slowly turn the pressure regulator knob clockwise

to increase the pressure. You should notice

movement of the needle on the pressure gauge.

Adjust the pressure to 30 psi for testing.

6. With the spray wand assembled, operate the

trigger valve and check it for leaks. Note the

trigger lock. Also adjust the nozzle and angle

adapter orientation to the desired position.

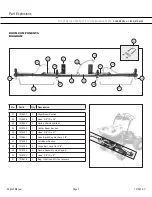

7. Turn off the switch. Turn on the boom line valve

and all four caps on the top of each boom nozzle

body.

8. Turn on the switch and observe the spray pattern

from each boom nozzle. Check the entire boom

assembly for leaks.

9. Flush out the water and antifreeze. Once the unit

has been pressure tested and you are familiar

with its operation, you can begin the calibration

procedure.