Model SR7010

i

Wall Mount Platform Scale

Operating and Service Manual

Part No. MAN7010

i

_150908

Page 10 of 14

S

Instruments, Inc.

,

600 Young Street, Tonawanda, NY 14150

Tel: 716-693-5977 Fax: 716-693-5854 URL:

www.srscales.com

email:

sri@srinstruments.com

Copyright 2015

S

Instruments, Inc.

L O W

L IM IT

A P P L IE D

L O A D

H IG H

L IM IT

9 9 .9

1 0 0 .0

1 0 0 .1

1 9 9 .8

2 0 0 .0

2 0 0 .2

2 9 9 .7

3 0 0 .0

3 0 0 .3

3 9 9 .6

4 0 0 .0

4 0 0 .4

4 9 9 .5

5 0 0 .0

5 0 0 .5

5 9 9 .4

6 0 0 .0

6 0 0 .6

6 9 9 .3

7 0 0 .0

7 0 0 .7

7 9 9 .2

8 0 0 .0

8 0 0 .8

8 9 9 .1

9 0 0 .0

9 0 0 .7

9 9 9 .0

1 0 0 0 .0

1 0 0 1 .0

C A L IB R A T IO N

T O L E R A N C E T A B L E

CALIBRATION

NOTE:

Ensure that nothing is in contact with the scale system during

this procedure. Remove hands from the system when noting the

displayed calibration results.

CHECKING CALIBRATION

STEP 1:

Select known calibrated weights, traceable to NIST.

NOTE: DO NOT USE

barbells or uncalibrated weights.

STEP 2:

Zero the scale by pressing and holding the left

ZERO

button.

STEP 3:

Place the calibrated weight on the scale. Wait for scale to

stabilize; note scale reading.

STEP 4:

Scale readings should be within Calibration Tolerance Table

(

Figure 3

)

Figure 3: Calibration Table

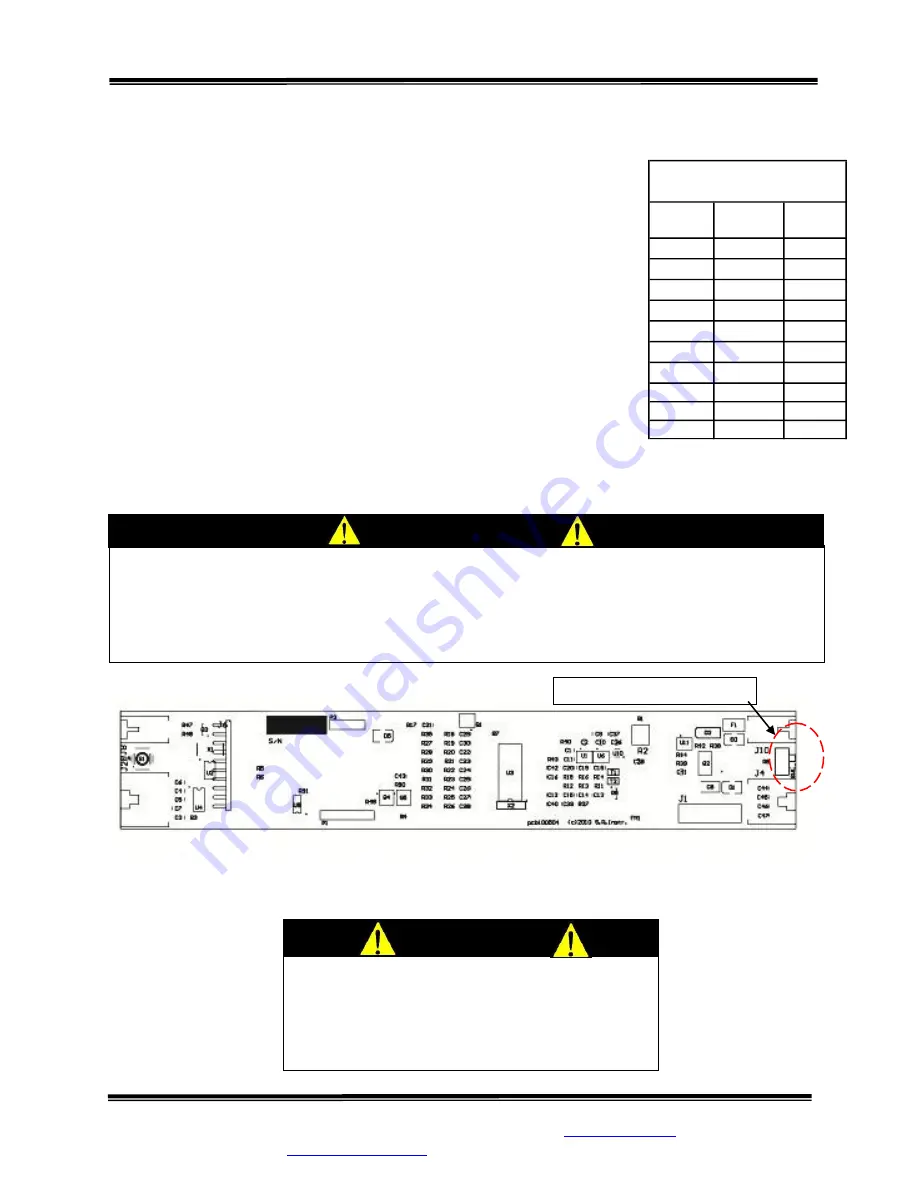

Figure 4: Calibration Switch Diagram

IMPORTANT

CALIBRATION Qualified service personnel only should perform this procedure. The

SR7010

i

load cells have no user serviceable components and should not be tampered with

for any reason. Re-calibration is generally not required, but should be verified

periodically to ensure accuracy. The recommendation for calibration check is at least

once every 12 months, or as individual maintenance policy requires.

CALIBRATION SWITCH

CAUTION

The integrated circuits and semiconductors on

the printed circuit boards may be damaged

by electrostatic discharge (ESD). Be sure to

use proper handling precautions at all times.

Continued next page