Series WTH

Page 23

LT105 Feb. 2019

Installation

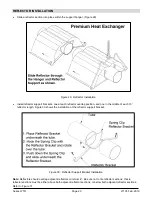

– Premium Heat Exchanger

Installation Sequence

Generally, there is no unique sequence for installation of the burner or heat exchanger. A review of the job site will

usually indicate a logical installation order. However, time and expense can be saved if installation is begun at the

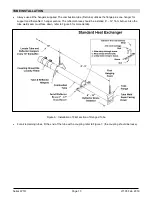

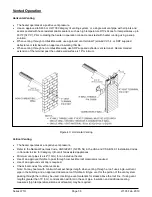

most critical dimension, watching for interference from overhead doors, cranes, auto lifts etc. Figure 20 provides a

general overview of the components utilized in the installation, as well as their general relationship.

Figure 20: General Overview of Installation

A general ordered sequence for installation is provided below for reference.

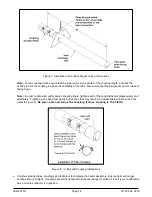

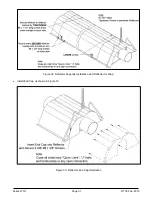

HANGERS INSTALLATION

Suspension mechanism must allow for lateral tubing expansion. A minimum 12" length welded link chain with a

working load limit of at least 200 lbs. is recommended (refer to Figure 21 for more details). SRP recommends

and make available “quick links” for connecting chain. If any open ended turnbuckles are used, the open ends

must be closed to avoid unhooking chain with inadvertent contact.

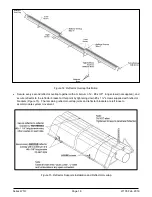

Locate hanging chain at predetermined suspension points in the structure. It is required that the first 2 hangers

be about 8' to 9' away. Thereafter, 10' apart on average is acceptable for the remainder of the heat exchanger.

At no time should hangers be more than 12' apart, (see Figure 22).