OM600 ENGINE MECHANICAL 1B3-89

14. Measure crankshaft bearing journal diameter (F).

Notice

When measured in A and B, the runout should not exceed

0.010mm.

8. Thoroughly clean the oil gallery.

9. Select a proper new bearing shells with reference to table.

10. Coat the new bearing shells with oil and insert into the

crankcase and into the crankshaft bearing caps.

Notice

Do not mix up upper and lower crankshaft bearing shells.

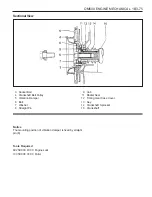

11. Install the bearing caps according to marking and tighten

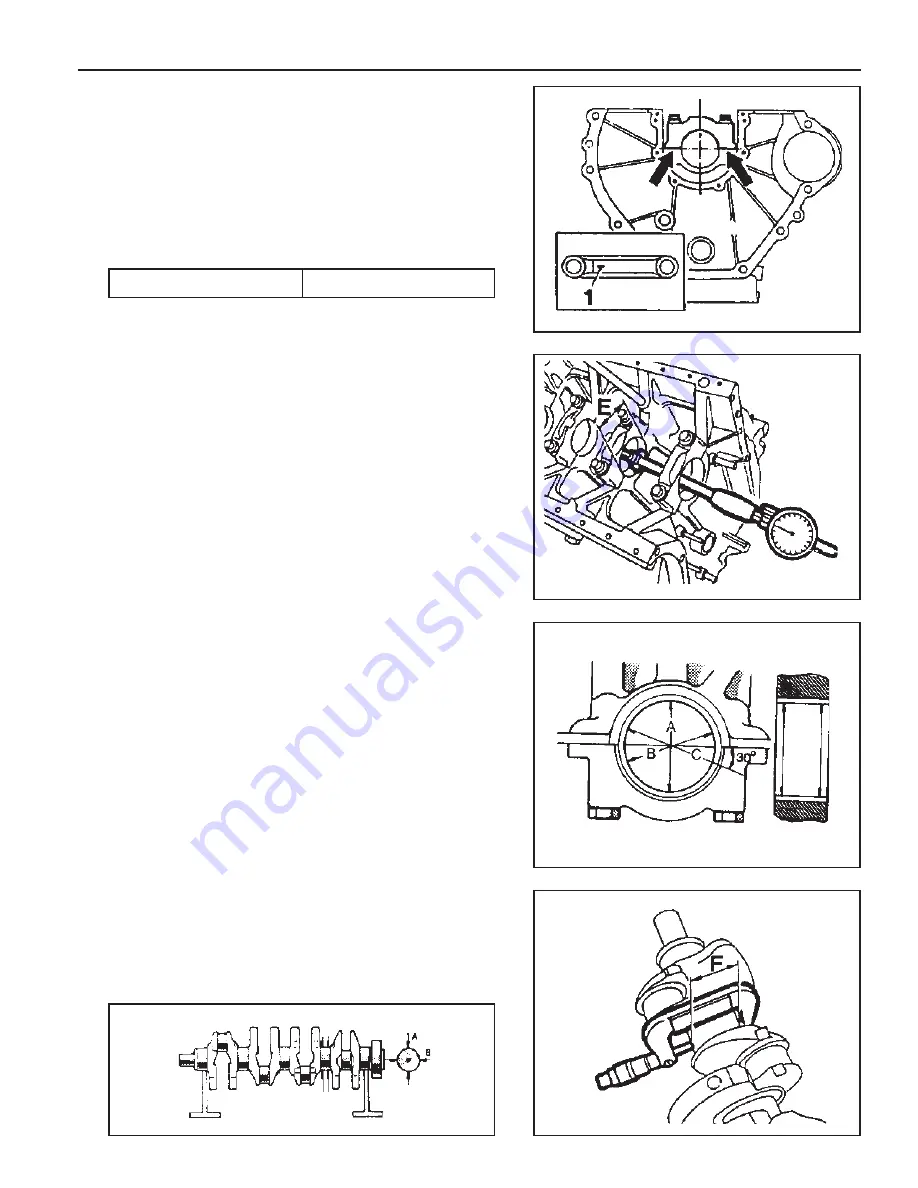

the 12-sided stretch bolts.

Tightening Torque

35 - 40 Nm

Notice

No. 1 is vibration damper side.

12. Measure crankshaft bearing diameters (E).

Extension 366 589 00 21 05

13. Measure at 3 points (A, B and C) and if the average value

of B and C is less than A’ s value, the average value of B

and C is the mean value and if more than A’ s value, A’ s

value is the mean value.

Summary of Contents for OM600

Page 12: ...1B3 12 OM600 ENGINE MECHANICAL MAINTENANCE AND REPAIR ON VEHICLE SERVICE ENGINE ASSEMBLY ...

Page 51: ...OM600 ENGINE MECHANICAL 1B3 51 49 Remove the cylinder head 2 and gasket 3 OM661LA ...

Page 145: ...OM600 ENGINE MECHANICAL 1B3 145 CHAIN TENSIONER 1 Chain Tensioner 80Nm 2 Seal Replace ...

Page 171: ...1B3 172 OM600ENGINE MECHANICAL Oil Circulation ...

Page 172: ...OM600 ENGINE MECHANICAL 1B3 173 Oil Filter a From Oil Pump b To Main Oil Gallery c To Oil Pan ...